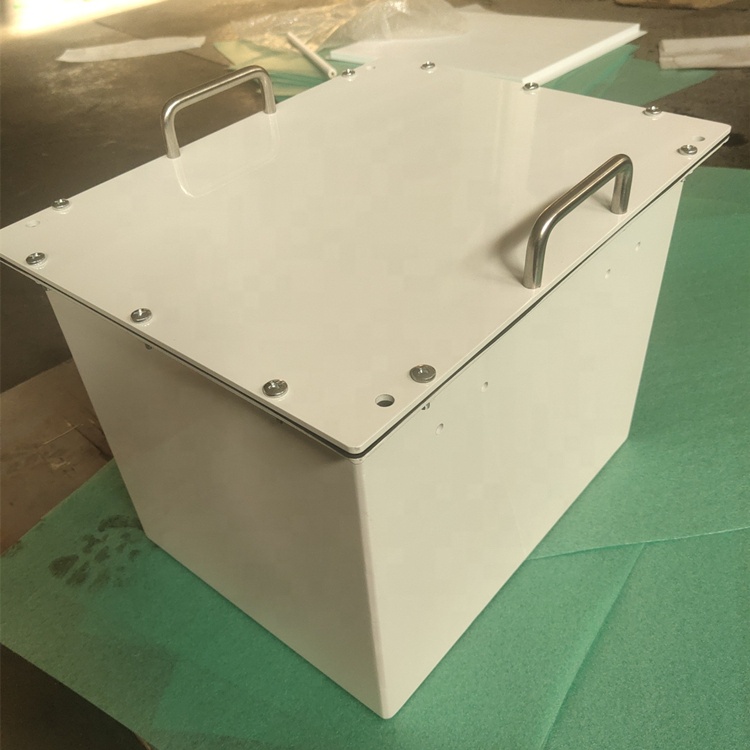

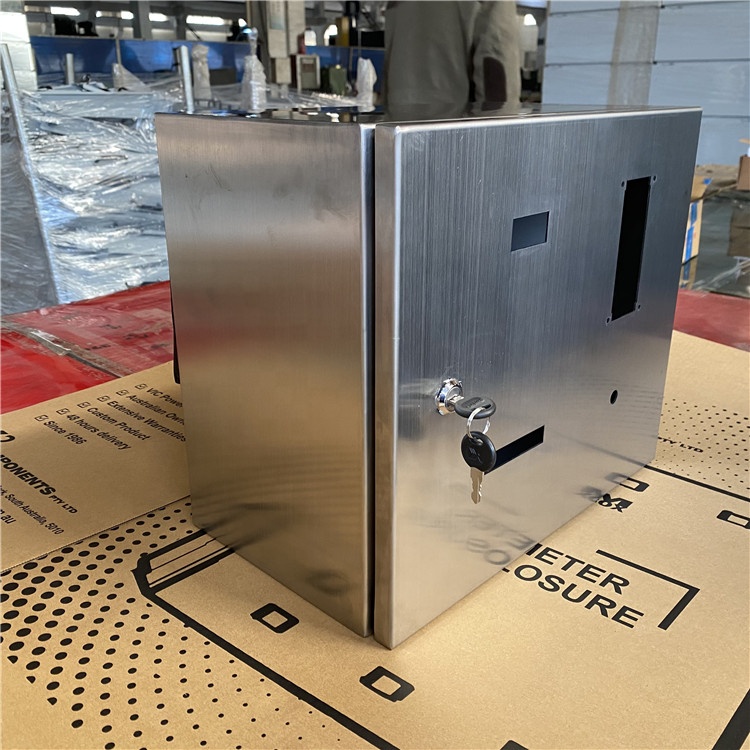

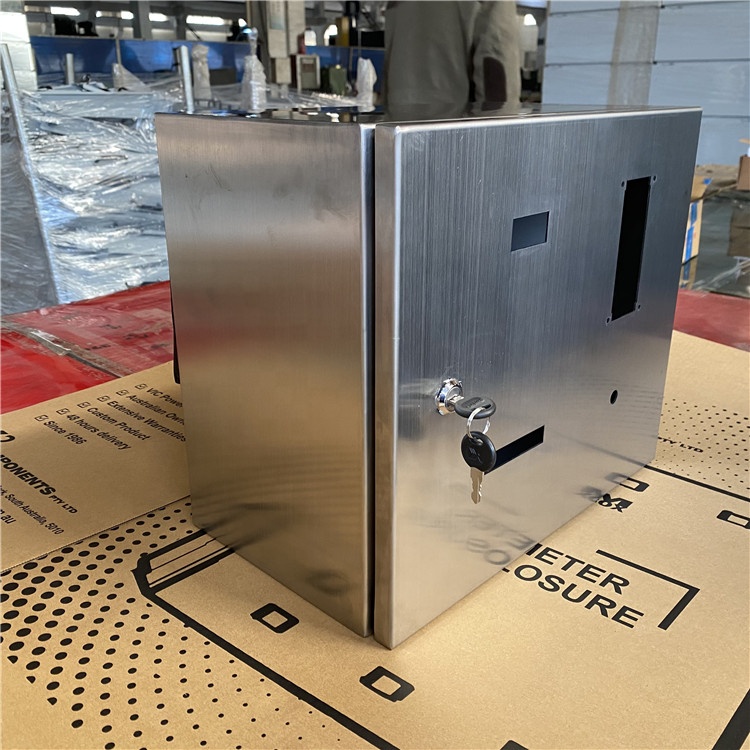

custom Custom 316L stainless steel medical sheet metal cabinets

Stainless Steel 316L

A molybdenum-enhanced austenitic alloy (2-3% Mo content) meeting ASTM A240 specifications, 316L stainless steel demonstrates superior performance in aggressive environments. Key characteristics include:

-

Enhanced Corrosion Resistance

- Mo addition elevates pitting resistance equivalent (PRE) to ≥28, outperforming 304 stainless in chloride-rich environments (coastal/chemical applications)

- Maintains integrity in pH 4.5-9.5 conditions with ≤100ppm chloride concentration

-

Material Composition

- Low-carbon variant (≤0.03% C) minimizes carbide precipitation during welding

- Balanced Cr/Ni/Mo ratio (16-18% Cr, 10-14% Ni, 2-3% Mo) ensures stable passive layer formation

-

Industrial Applications

- Medical equipment (ISO 13485 compliant implant components)

- Marine hardware (ASTM G48 Method A certified for saltwater resistance)

- Chemical processing vessels (resists organic acids and sulfides)

-

Processing Considerations

- Requires post-weld solution annealing (1040-1100°C) to restore corrosion resistance

- Achieves Ra 0.8μm surface finish through mechanical polishing techniques

This alloy’s dual-certification (ASTM/GB standards) makes it preferred for critical applications where standard 304 stainless proves inadequate against localized corrosion.

Custom stainless steel cabinets are extensively utilized in medical applications due to the material’s cost-effectiveness,

high strength, and superior corrosion resistance. These properties ensure compliance with strict medical sterilization requirements.

The manufacturing process involves precision sheet metal bending and welding techniques, with spot welding specifically employed to minimize heat-induced deformation. Final finishing through wire brushing and polishing eliminates all production marks, delivering clean and durable medical-grade equipment.

Introduction Of Sheet Metal Laser welding/ARC welding/TIG Welding Parts

|

| Item Name : |

Laser welding/ARC welding/TIG Welding Parts

|

| Material : |

galvanized Steel sheet or carbon steel material |

| Dimension : |

Per your drawings |

| Min Tolerance : |

±0.2mm |

| Manufacturing Services : |

Design & OEM Manufacturing |

| Craftsmanship : |

Laser cutting + sheet metal bending + ARC/TIG welding + power coating |

| Drawing Software: |

CAD/Solidworks/PDF |

| Delivery Date : |

10-15 Working Days |

|

Need a quick start on your next custom stainless steel cabinet project?

Contact our team of experts for quick access to genuine manufacturer quotes and full technical support services.

Welding Process Standards & Technical Specifications

1. Process Parameters

- Key Variables: Electrode diameter, welding current (regulated per equipment specifications), arc voltage (20-30V range), travel speed (optimized for material thickness)

- CO₂ Gas Shielded Welding: Includes wire diameter (0.8-1.2mm), gas flow rate (15-25L/min), and parameter coordination per GB/T 5185-2005/ISO 4063:1998

2. Method Classification

- Fusion Welding:

- TIG (AWS GTAW): For stainless steel/copper/aluminum (ISO 4063 Code 141)

- CO₂ (GMAW): Carbon steel structures (ISO 4063 Code 135)

- Resistance Welding:

- Spot welding (ISO 4063 Code 21): Sheet metal assemblies

- Projection welding: Enhanced joint strength

3. Quality Assurance

- Deformation Control:

- Fixture optimization (clamping force ≥3kN)

- Sequence planning: Symmetric welding paths

- Post-weld correction: Flame straightening (≤800°C)

- Defect Prevention:

- Pre-weld cleaning (Sa 2.5 surface preparation)

- Interpass temperature monitoring (60-150°C range)

4. Material Compatibility

| Material |

Recommended Process |

ISO Code |

| Carbon Steel |

CO₂ GMAW |

135 |

| Stainless Steel |

Pulsed TIG |

141 |

| Aluminum |

AC TIG with Argon Shield |

141 |

5. Robotic Implementation

- 6-axis systems achieving ±0.1mm repeatability

- Adaptive parameter control: Real-time current/voltage adjustment

6. Standard Compliance

- Dimensional tolerance: EN ISO 13920-B

- Weld symbolization: AWS A2.4 compliant

- Documentation: WPS/PQR per ASME Section IX

This technical framework integrates ISO 4063 coding with process parameter optimization, ensuring compliance with GB/T 5185-2005 while maintaining interoperability with international welding standards.

Yantai Deshibo Precision Machinery Co., Ltd., established in 2021 and based in Yantai’s Zhifu District, specializes in precision sheet metal fabrication with a 5,000-square-meter production facility. The company employs over 150 staff, including a technical team comprising 25% of its workforce. It focuses on customized metal cabinet solutions for diverse industrial applications, utilizing materials such as stainless steel (including SUS304), aluminum alloys, and carbon steel. The organization demonstrates strong process optimization capabilities through initiatives like improved packaging systems with transparent inspection windows and innovative CNC machining tooling designs, ensuring product integrity during logistics while maintaining close-tolerance manufacturing standards.

Yantai Deshibo Medical Cabinet Features

-

Material Selection

- Medical-certified 316L alloy (Mo 2-3%) with nickel-free composition prevents pharmaceutical contamination

- Maintains <0.03% carbon content through vacuum melting technology

-

Surface Engineering

- Precision #240 abrasive finishing (Ra≤0.8μm) with electrochemical passivation treatment

- Fingerprint-resistant coating achieves 85+ light reflectance value

-

Structural Performance

- Cold-rolled forming ensures 210-310HV hardness with ≤0.5mm/m straightness tolerance

- Medical-grade hinges withstand 50,000+ open/close cycles (EN 60601-1 compliant)

-

Environmental Adaptability

- Maintains corrosion resistance at 60°C/95%RH conditions (ISO 6270-2 standard)

- Passes 96hr salt spray test (ASTM B117) without red rust formation

This technical configuration meets GB/T 4234 medical equipment requirements while achieving Class 1000 cleanroom compatibility.