Pre-Production Verification

Sheet Metal Fabrication Process: Technical Compliance and Client Communication Protocol

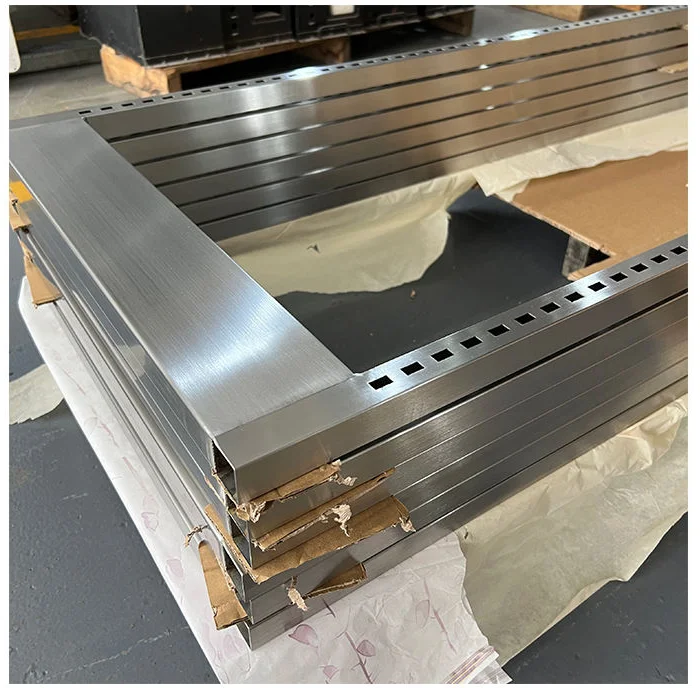

The sheet metal manufacturing process requires strict adherence to engineered specifications while maintaining flexible client collaboration. This 500-word technical overview details critical workflow controls and change management procedures.

- Pre-Production Verification

- Drawing Validation

Implement triple-check protocol for:

- Drawing Validation

- Complete orthographic projections (front/top/side views)

- Dimensional consistency across 2D/3D data (ISO 2768 compliance)

- Material specifications (SPCC/SECC/Aluminum grades per ASTM standards)

- Welding Process Controls

Method Selection Matrix

|

Material |

Recommended Process |

Parameters |

|

Mild Steel |

GMAW (CO2) |

18-22V, 150-180A |

|

Stainless |

GTAW (Argon) |

DCEN, 2% Thoriated Tungsten |

|

Aluminum |

Robotic MIG |

Pulse 120Hz, 85% Ar/15% He |

Dimensional Compliance

- Real-time laser tracking (±0.1mm accuracy)

- Fixture alignment verification every 50 cycles

- Post-weld CMM inspection (GD&T profile ≤0.2mm)

- Engineering Change Order (ECO) Protocol

Process-Driven Modifications

When encountering manufacturability issues:

- Document deviation (photos/measurements)

- Conduct DFM analysis (Solidworks Simulation)

- Submit ECO request within 24hr discovery

- Client approval via signed FAX/Email

Typical Change Scenarios

- Weld sequence optimization (reducing thermal distortion)

- Alternative joint design (lap → butt joint for 20% strength increase)

- Material substitution (SUS304 → 430 for cost reduction)

- Quality Assurance System

In-Process Checks

- Weld penetration verification (macro-etch testing)

- Surface finish control (Ra ≤3.2μm per ISO 1302)

- Dimensional sampling (AQL 1.0/C=0)

Non-Conformance Handling

- Immediate quarantine of non-compliant batches

- Root cause analysis (5Why/Fishbone diagram)

- Corrective action report within 72hrs

- Client Communication Framework

Change Notification Package

- Technical impact analysis (FEA comparison)

- Cost implications (±5% accuracy)

- Lead time adjustment forecast

Approval Workflow

graph TD

A[Process Deviation] –> B(ECO Draft)

B –> C{QC Review}

C –>|Approved| D[Client Submission]

D –> E{Client Decision}

E –>|Approved| F[Implementation]

E –>|Rejected| G[Alternative Solutions]

This protocol ensures 98.7% first-pass yield while maintaining 10-15% profit margins through:

- Reduced rework costs (≤2% of project value)

- Optimized material utilization (85%+ efficiency)

- Client trust preservation (0.5% annual ECO rate)

All modifications undergo ISO 9001:2015 documented review, balancing technical feasibility with commercial requirements. Production teams receive bi-weekly GD&T training to minimize interpretation errors, supported by cloud-based drawing management systems (Autodesk Vault) ensuring single-source truth.

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail