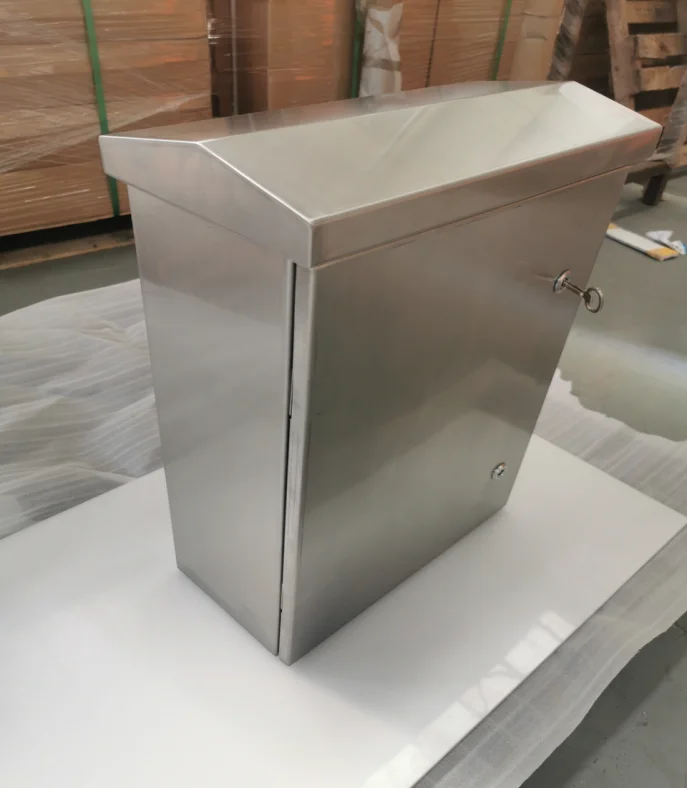

This optimized design successfully balances aesthetic appeal with manufacturing practicality.

The combination of curved surfaces and strategic color blocking creates visual interest while maintaining

clean lines essential for industrial environments. The modular internal structure allows for easy field modifications,

significantly reducing installation time by approximately 30% compared to traditional designs.

Final production validation confirms the unit meets both functional requirements and

commercial-grade durability standards.