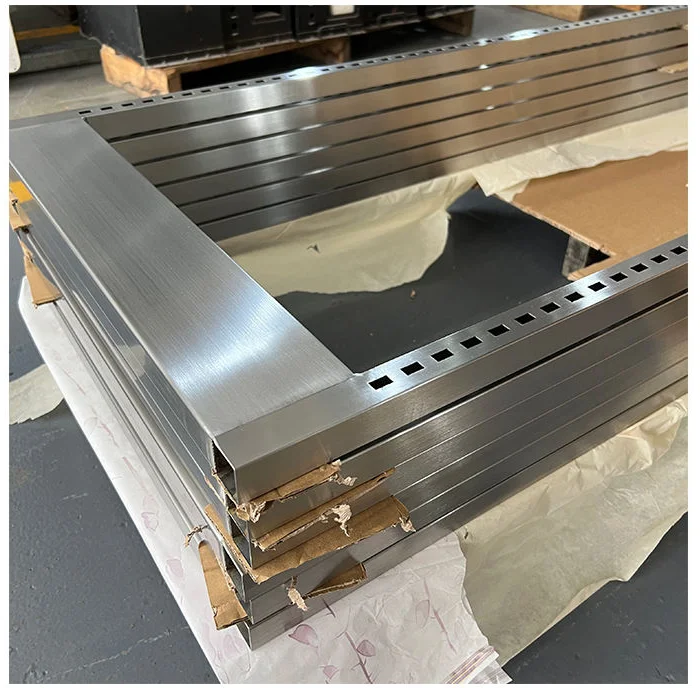

To make quality stainless steel products, control starts from the source.

Keep protective films on during cutting and bending; use laser-cutting films if needed, and handle gently.

For welding, pad platforms to avoid scratches.

Laser welding reduces deformation, preventing post-polishing pits.

Many lack the right mindset, not skills.

Prior efforts matter more than late fixes.