Pre-Production Verification

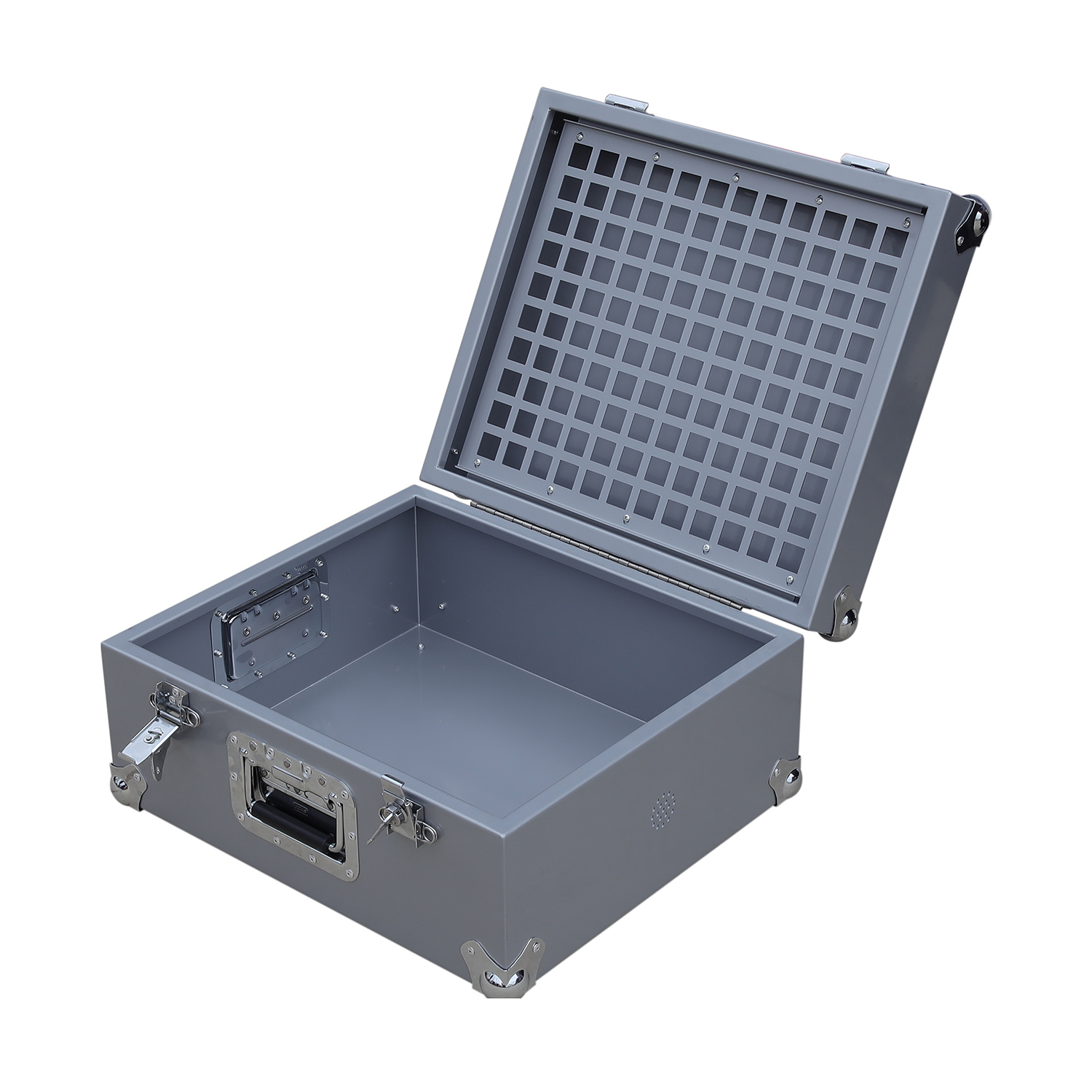

Optimized Outdoor Battery Cabinet Design: Material Selection and Surface Treatment Evolution

- Initial Design Challenges

Our first-generation outdoor battery cabinet utilized cold-rolled steel sheets (SPCC) with conventional spray painting (60μm polyester powder). Field observations after 12-month deployment revealed:- Base panel corrosion (3-5mm rust spots)

- Edge coating peeling (particularly at weld seams)

- 15% reduction in surface hardness (from 2H to H pencil grade)

- Failure Analysis

The corrosion mechanism was identified through cross-sectional microscopy:

- Pinhole defects in coating (Ø0.1-0.3mm)

- Electrochemical migration at steel-coating interface

- Salt deposition accelerated by capillary action

- Material Upgrade Strategy

3.1 Substrate Optimization

Adopted hot-dip galvanized steel (Z275 grade) with:

- 20-25μm zinc coating (per ASTM A653)

- Spangle-free surface for better adhesion

- Comparative advantages:

|

Parameter |

Cold Rolled Steel |

Galvanized Steel |

|

Corrosion Resistance |

500hrs NSS* |

1000hrs NSS |

|

Paint Adhesion |

4B (ASTM D3359) |

5B |

|

Cost Premium |

– |

+18% |

*Neutral Salt Spray test per ISO 9227

3.2 Coating System Enhancement

Implemented two-coat system:

Zinc-rich Primer (80% Zn in epoxy matrix)

- Cathodic protection for cut edges

- 25-30μm DFT (Dry Film Thickness)

Weather-resistant Topcoat

- Polyurethane hybrid powder (RAL 7035)

- UV stability: ΔE<1 after 2000hrs QUV

- Impact resistance: 50kg·cm (ASTM D2794)

- Process Validation

4.1 Surface Preparation- Six-stage pretreatment:

- Alkaline degreasing (50℃, pH 11-12)

- Phosphating (ZnCaPO4, 2-3μm)

- Chromium-free passivation

- Deionized water rinse

- Drying (140℃, 20min)

- Electrostatic charging (60-80kV)

4.2 Coating Application

- Automated robotic spraying:

- 85% transfer efficiency

- ±5μm thickness control

- 15min curing at 200℃

- Alternative Process Evaluation

5.1 Aluminum Alloy Consideration

Rejected due to:- 40% longer welding cycle (required TIG welding)

- 5x material cost (5052 vs galvanized steel)

- Surface treatment complexity (needing chromate conversion)

5.2 Electrophoretic Coating

Discarded for:

- Tank size limitation (max 2.5m vs cabinet’s 3.2m)

- 30% higher energy consumption

- Difficulty in achieving >40μm coating

- Performance Verification

Accelerated testing results:

|

Test Item |

Standard |

Result |

|

Cyclic Corrosion |

SAE J2330 |

60 cycles (no red rust) |

|

Adhesion |

ISO 2409 |

Class 0 |

|

Thermal Shock |

-40℃↔80℃ |

10 cycles (no cracking) |

|

Abrasion Resistance |

Taber CS10 |

<10mg/1000 cycles |

- Production Implementation

- Achieved 95% first-pass yield

- Reduced per-unit processing time by 25%

- Enabled 5-year warranty against corrosion

This technical evolution demonstrates how systematic material selection combined with advanced coating technologies can solve outdoor equipment durability challenges. The final solution balances performance requirements (IP55 protection) with mass production feasibility (1,200 units/month capacity).

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail