Metal surface heat treatment is an important processing technology

Description :

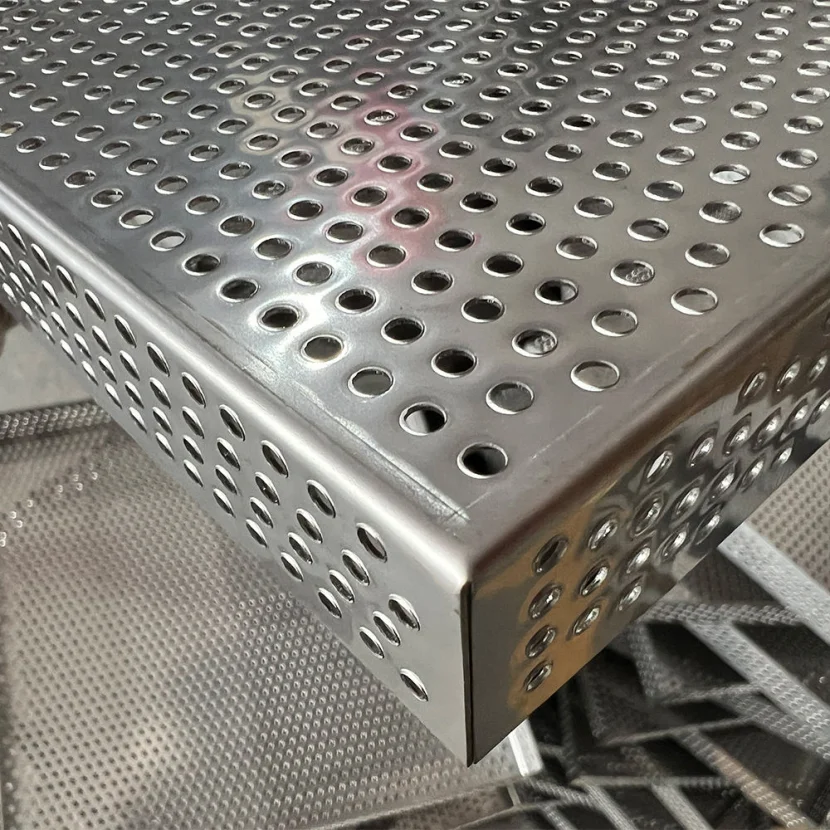

Metal surface heat treatment is an important processing technology for improving the internal structure and properties of metals.

The core purpose is to obtain the desired material properties by heating the metal to a certain temperature and then cooling it at an appropriate cooling method and rate. According to the different process objectives and cooling methods, metal heat treatment can be divided into three categories: integral heat treatment, surface heat treatment, and chemical heat treatment. Integral heat treatment is a comprehensive heating treatment of the workpiece, suitable for parts that require integral strengthening or transformation, including annealing, normalizing, quenching, tempering, surface heat treatment, and strengthening to maintain toughness on the surface of the workpiece.

It is suitable for parts that require surface wear resistance and core anti powder. Chemical liquid treatment involves penetrating elements such as carbon, nitrogen, boron into the surface to form a hardened layer, balancing surface wear resistance and core toughness

Comprehensive Analysis of Metal Heat Treatment: Principles, Classifications, and Industrial Applications

1. Fundamental Principles of Metal Heat Treatment

Metal heat treatment is a critical process that modifies the internal structure and properties of metals through controlled heating and cooling. This technique allows engineers to tailor material characteristics for specific applications without altering the component’s geometry. The core objectives include:

- Enhancing mechanical properties (hardness, strength, ductility)

- Improving corrosion resistance

- Relieving internal stresses from manufacturing processes

- Optimizing machinability

The process involves three key stages:

- Heating: Raising the metal to precise temperatures (typically 500-1200°C) to induce phase transformations

- Soaking: Maintaining temperature to ensure uniform structural changes

- Cooling: Controlling cooling rates (from 0.1°C/s to 1000°C/s) to achieve desired microstructures

2. Classification of Heat Treatment Processes

2.1 Bulk Heat Treatment

Applied to entire components for uniform property enhancement:

| Process |

Temperature Range |

Cooling Method |

Key Effects |

| Annealing |

700-900°C |

Slow furnace cooling |

Softens metal, improves ductility |

| Normalizing |

800-950°C |

Air cooling |

Refines grain structure |

| Quenching |

750-850°C |

Rapid oil/water cool |

Increases hardness |

| Tempering |

150-650°C |

Controlled air cool |

Reduces brittleness |

Industrial Example:

Automotive gears undergo:

- Carburizing (930°C for 6 hours)

- Oil quenching (830°C)

- Low-temperature tempering (180°C)

Resulting in:

- Surface hardness: 58-62 HRC

- Core toughness: 40-45 HRC

2.2 Surface Heat Treatment

Creates property gradients for specialized applications:

2.2.1 Induction Hardening

- Uses electromagnetic induction (1-500 kHz)

- Achieves 0.5-10mm case depth

- Typical applications: Gear teeth, camshafts

2.2.2 Flame Hardening

- Employs oxy-acetylene flames (3100°C)

- Travel speed: 50-150 mm/min

- Ideal for large dies and rail components

2.3 Chemical Heat Treatment

Modifies surface composition through element diffusion:

| Process |

Diffused Element |

Case Depth (mm) |

Surface Hardness (HV) |

| Carburizing |

Carbon |

0.3-2.0 |

700-900 |

| Nitriding |

Nitrogen |

0.1-0.6 |

1000-1200 |

| Boronizing |

Boron |

0.05-0.2 |

1500-2000 |

Diffusion Mechanism:

C in γ-Fe: D = 0.12exp(-138000/RT) mm²/s

Where:

- R = 8.314 J/mol·K

- T = Absolute temperature

3. Advanced Surface Engineering Technologies

3.1 Thermochemical Processes

Hot-dip Galvanizing (SGCC Steel):

- Zinc bath temperature: 445-465°C

- Coating structure:

- Γ phase (Fe₃Zn₁₀): 1-2μm

- δ phase (FeZn₇): 50-60μm

- ζ phase (FeZn₁₃): 20-30μm

Plasma Nitriding:

- Operates at 500-600V DC glow discharge

- Achieves 0.3mm case depth in 20 hours

- White layer control: <5μm

3.2 Coating Technologies

High-Velocity Oxygen Fuel (HVOF) Spraying:

- WC-12Co coatings reach 1200 HV hardness

- Porosity <1% for superior corrosion resistance

Physical Vapor Deposition (PVD):

- TiAlN multilayer coatings: 3000 HV

- Withstand temperatures up to 800°C

4. Material Selection Guide

| Base Material |

Recommended Treatment |

Performance Enhancement |

| SPCC (Cold-rolled) |

Phosphate + E-coating |

500h salt spray resistance |

| 6061 Aluminum |

Anodizing (15-25μm) |

Taber abrasion: 10mg loss |

| 304 Stainless |

Plasma Electrolytic Oxidation |

Surface hardness: 1500 HV |

| SGCC (Galvanized) |

Chromate Passivation |

1000h neutral salt spray survival |

5. Quality Assurance Systems

5.1 Non-Destructive Testing:

surface treatment

- Barkhausen noise analysis (±20MPa stress detection)

- Eddy current testing (±0.05mm case depth accuracy)

5.2 Metallographic Standards:

- Carburized case depth: EN ISO 2639

- Decarburization measurement: ASTM E1077

6. Industrial Applications

6.1 Automotive Industry:

- Engine blocks: T6 treatment for AlSi10Mg alloy

- Transmission gears: Vacuum carburizing process

6.2 Aerospace Components:

- Turbine blades: Directional solidification + TBC coatings

- Landing gear: Maraging steel aging treatments

6.3 Tool Manufacturing:

- HSS drills: Salt bath nitriding

- Die casting molds: TD process (vanadium carbide coating)

7. Environmental Considerations

- Wastewater treatment: CN⁻ <0.2mg/L (nitriding salt byproducts)

- Energy consumption optimization: 1.2-3.5 kWh/kg

- Sustainable alternatives:

- Gas nitriding (80% NOx reduction vs liquid processes)

- Pulse plasma technology (40% energy savings)

8. Future Technological Trends

This comprehensive approach to metal treatment combines centuries-old metallurgical wisdom with cutting-edge technologies. From ancient fire-hardening techniques to modern plasma-enhanced processes, heat treatment continues to evolve, enabling manufacturers to push the boundaries of material performance while meeting increasingly stringent environmental standards. The strategic selection and application of these processes remain crucial for developing durable, high-performance components across industries.