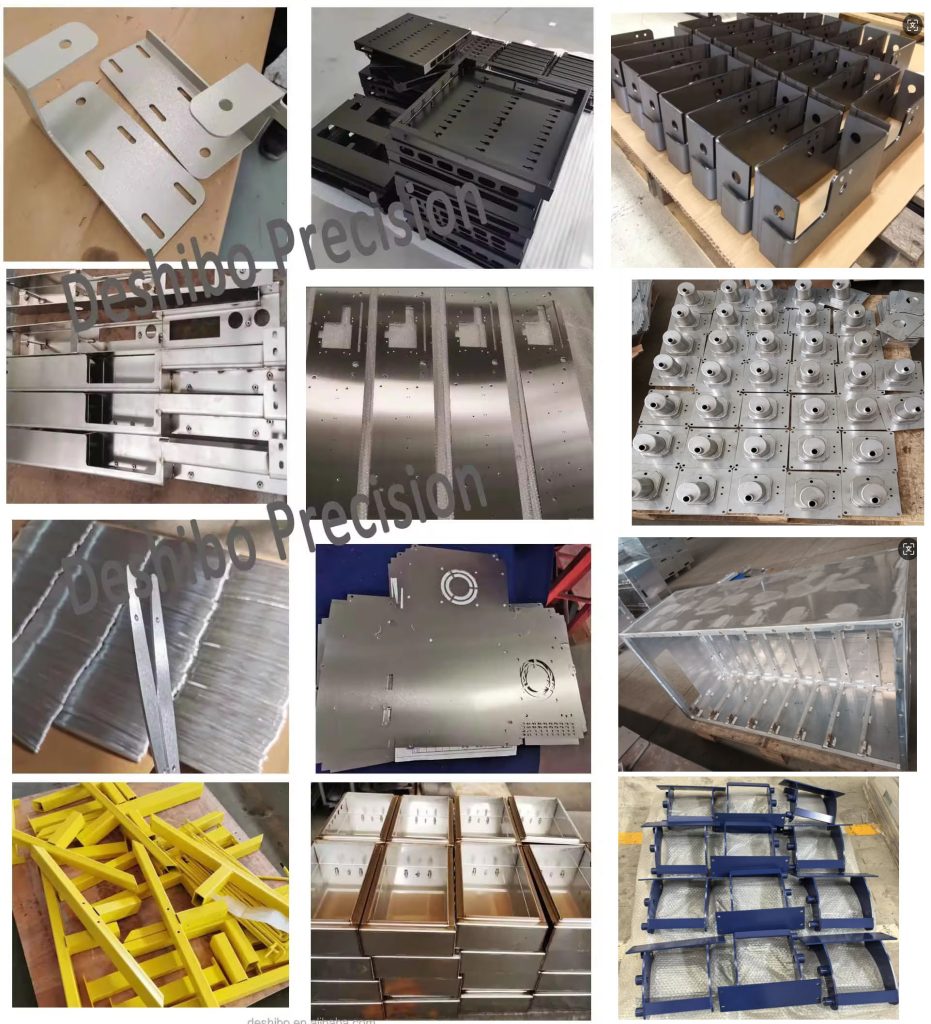

Sheet metal laser cutting uses high-powered lasers to precisely cut or engrave metal sheets (e.g., stainless steel, aluminum, carbon steel)

into complex shapes.

This technology offers exceptional accuracy, smooth edges, and minimal material waste. Ideal for industries like automotive, aerospace, electronics, and construction,

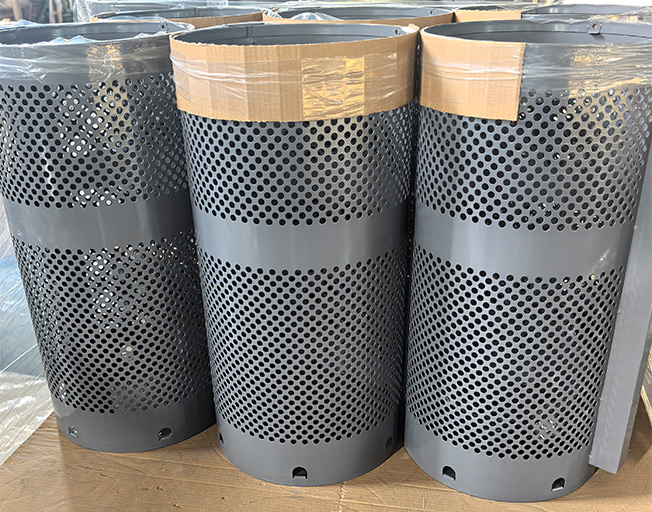

it enables rapid prototyping and mass production of components such as brackets, panels, and enclosures.

Advanced CNC systems and CAD/CAM software ensure repeatability and customization.

Laser cutting is faster than traditional methods, supports intricate designs, and reduces post-processing needs. Fiber and CO2 lasers are common, with fiber lasers excelling in cutting reflective metals. Quality control ensures dimensional accuracy and consistency,

making it vital for modern manufacturing efficiency