From raw material to finished product, every process embodies the spirit of craftsmanship

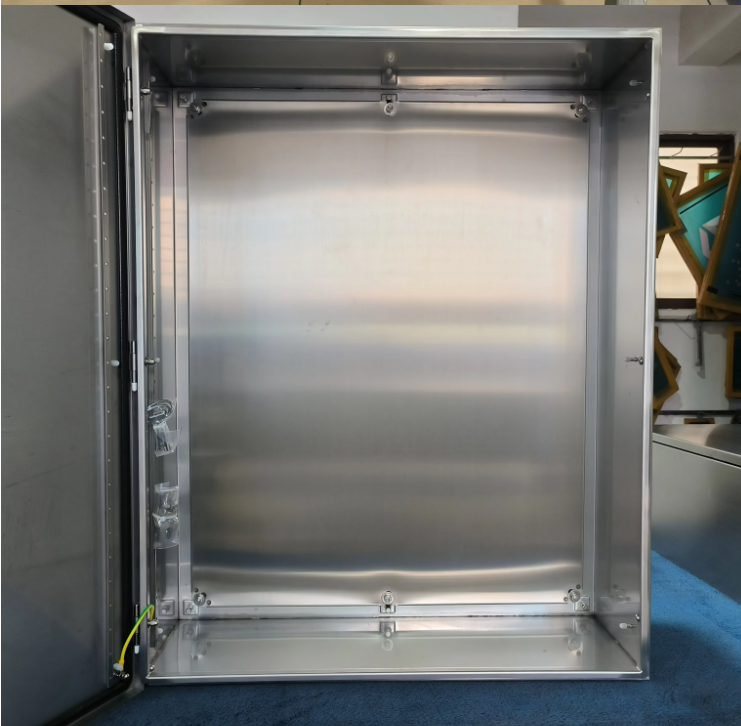

Description :

Making every sheet metal part a masterpiece of precision engineering