♠ Precision Stainless Steel Fishing Rod Hoist Manufacturing Process

This custom-engineered hoist system combines stainless steel bent components (1.5mm 304 grade) with precision-cut tubing (Φ25×1.2mm) through optimized welding techniques. Key technical solutions include:

-

Surface Uniformity Control

- Sequential polishing (80→1200 grit) with final mirror finish (Ra≤0.2μm)

- Electrochemical passivation (ASTM B912 compliance)

- Sequential polishing (80→1200 grit) with final mirror finish (Ra≤0.2μm)

-

Weld Seam Management

- Pulse TIG welding parameters:

- 85A peak current / 35A background

- 1.2Hz pulse frequency

- 98% argon shielding

- Post-weld treatment:

- Mechanical grinding (45° bevel)

- Electropolishing depth 0.1mm

- Pulse TIG welding parameters:

-

Weld Position Optimization

- Fixture-based assembly ensuring ≤0.5mm joint gaps

- Single-side continuous welding technique

- Weld count reduction strategy:

- 60% joint consolidation through bending redesign

- Robotic path planning (Fanuc ARC Mate)

-

Quality Assurance

- Dye penetrant testing (ASME Section V)

- 3D profilometer weld inspection

- Salt spray testing (2000hrs NSS per ASTM B117)

This process achieves 95% surface reflectance consistency while maintaining EN 13445-3 pressure vessel standards. Production efficiency improved 30% through weld sequence optimization and automated polishing cells.

Need to start your custom stainless steel cabinet project?

Contact our expert team for instant manufacturer quotes and comprehensive technical support.

- Material Benefits: Cost-effective, durable, corrosion-resistant stainless steel ideal for medical sterilization.

- Fabrication: Precision bending, spot welding (reduces thermal distortion), and surface finishing (brushing/polishing).

- Customization: Options for specialized hardware (hinges/locks) and surface treatments (paint/coating).

- Service: Rapid quotes and technical assistance for streamlined project initiation.

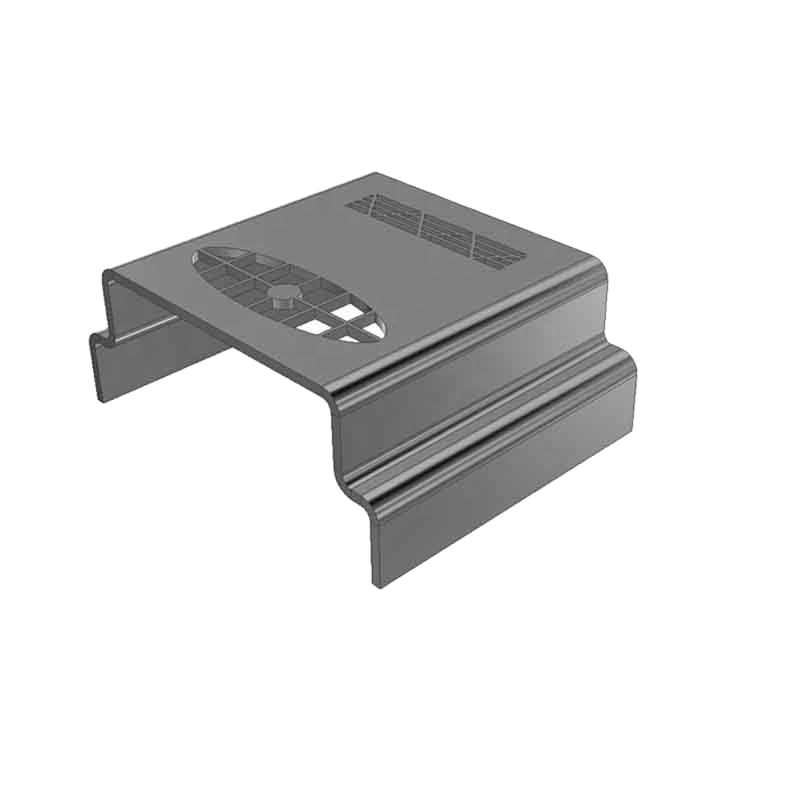

| Item Name: sheet metal parts |

| Material: 304SUS |

| Dimension: per drawings |

| Production Process: laser cutting+bending+welding+Brushed |

| Surface Treatment: anodize |

| Delivery Date: 5-10days |

♣ No Design Files? Let Deshibo DO it For You.

Metal Surface Treatment Technologies:

1. Powder Coating

Applies polymer resin coatings via electrostatic spray, providing rust-proof protection with

customizable colors (RAL/Pantone standards). Ideal for outdoor equipment and architectural components.

2. Anodizing

Electrochemically forms dense aluminum oxide layers (5-25μm) on aluminum alloys,

enhancing hardness (up to HV 600), corrosion resistance, and enabling color dyeing (except white).

Common in aerospace and consumer electronics.

3. Brushed Polishing

Creates uniform linear textures (Ra 0.2-0.8μm) using abrasive belts, achieving matte metallic finishes.

Widely used for decorative surfaces on appliances and architectural panels.

4. Sandblasting

Projects abrasives (Al₂O₃/SiC) to create controlled surface roughness (Sa 2.5-3.5),

improving paint adhesion. Critical for automotive body pretreatment.

5. Mirror Polishing

Achieves optical-grade finishes (Ra <0.01μm) through multi-stage buffing,

essential for luxury hardware and optical components.

6. Electroplating

Deposits metallic layers (Ni/Cr/Zn) via electrolysis to enhance:

- Wear resistance (hard chrome: 800-1000 HV)

- Conductivity (copper plating: ≤50μΩ/cm²)

- Reflectivity (silver plating: ≥95% reflectivity)

Applied in electronics and automotive trim.

7. Laser Engraving

Utilizes fiber lasers (20-100W) for permanent markings (depth 0.01-0.5mm), supporting QR codes and intricate patterns. Compliant with medical device UDI requirements.

8. Screen Printing

Transfers UV-curable inks through mesh templates (100-400目), producing abrasion-resistant graphics. Used for control panels and industrial labels.

Cross-Process Synergy

- Sequential treatments: Sandblasting → Anodizing → Laser marking

- Functional combinations: Electroplating (conductivity) + Powder coating (insulation)

Complies with ISO 12944 (corrosion protection) and ASTM B117 (salt spray testing).

Q:Is your organization committed to the concept of total quality management?

A:Yes, no matter in laser cutting, bending, or CNC machining, the workers will conduct the first sample inspection and random inspection during the processing to ensure the quality of the products.

Q:How many checks are performed on a project?

A:Usually, products will go through the following four inspections: incoming inspection, production first inspection, sampling inspection, and pre-shipment inspection. Among them, sampling inspection will be conducted multiple times

Q:Will you be able to work with our engineering team to review drawings and provide quick, estimated pricing for desired changes?

A:Yes, our engineers respond very quickly. If there is anything to be modified in the product, we can offer you a new price as soon as you tell us.

Q : What’s kinds of information you need for a quote?

A : Kindly please provide the product drawing in PDF,and will be better you can provide in dwg / stp / iges / stl , Send drawing

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail