What is the Difference Between CNC Cutting and Laser Cutting?

Time : Aug 28, 2025 View : 521

Overview of CNC Cutting and Laser Cutting Technologies

Defining CNC Cutting in Modern Manufacturing

CNC (Computer Numerical Control) cutting is a method that shapes materials using tools guided by computer programs. In metal CNC machining, it involves tasks like milling, drilling, turning, or grinding to create precise parts from metal sheets or blocks. This process is very automated. It can make complex shapes with great accuracy.

At Yan Tai Deshibo Metal Products Co., Ltd., metal CNC machining includes techniques like drilling, turning, and grinding. These methods craft parts from materials such as stainless steel, mild steel, aluminum, and brass. The company has skilled CAD designers and engineers. They work directly from client drawings or help create new designs.

Introduction to Laser Cutting of Metal Sheets

Laser cutting of metal sheets uses a strong beam of light to cut materials. The beam melts or burns the metal along a planned path. This method doesn’t touch the material. It’s great for cutting thin metal sheets with high detail and little damage. It works well for tricky patterns or fine cuts that are hard to do with regular tools.

At Yan Tai Deshibo, laser cutting of metal sheets is part of their full fabrication services. They cut stainless steel, aluminum, and other metals. After cutting, they can bend, weld, or finish the parts with processes like anodizing or powder coating.

Key Differences in Cutting Mechanisms

How CNC Machines Remove Material Mechanically

CNC machines use spinning tools, like drills or end mills, to carve away material. This physical process creates metal chips. The tool must touch the material to work. Computer instructions, based on CAD models, guide the tool’s path exactly.

In metal CNC machining, methods like drilling, milling, and turning are used. These are cold processes. They keep the metal’s quality and ensure accurate sizes. They’re great for parts needing features like threads or deep holes.

How Laser Cutters Use Heat and Light to Cut Materials

Laser cutting of metal sheets works differently. It uses heat from a powerful laser beam. The beam heats the metal until it melts or turns to gas. Gases like oxygen or nitrogen blow away the melted material. This helps make clean edges.

This method allows for very detailed cuts without wearing out tools. However, the heat can slightly affect the metal near the cut. Manufacturers must plan for this during later steps.

Precision and Tolerances in Metal Fabrication

Accuracy Levels Achieved Through Metal CNC Machining

Metal CNC machining is famous for being very precise. It can repeat the same cut perfectly every time. Depending on the tools and materials, it can achieve tolerances as tight as ±0.01 mm. This makes it perfect for important parts in industries like aerospace, cars, medical tools, and electronics.

Yan Tai Deshibo uses advanced CNC systems. They also check parts carefully using 3D models. This ensures every piece is consistent and meets high standards.

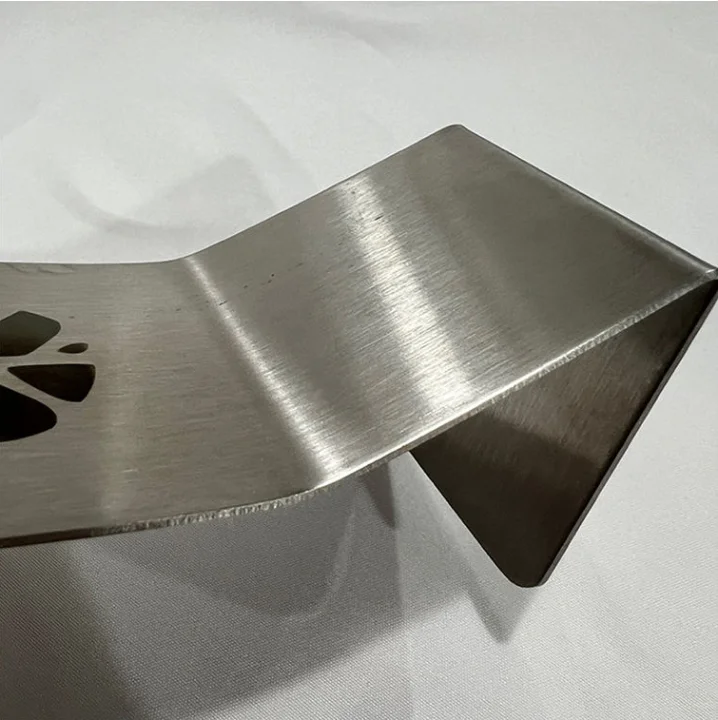

Fine Detailing Capabilities of Laser Cut Steel Sheet

Laser cut steel sheet is excellent for making detailed shapes. It can create sharp corners and smooth edges. This is ideal for decorative panels, electronic cases, or signs. The laser’s thin cut allows parts to be placed close together on a sheet. This saves material.

In processes like sheet blanking, laser cut steel sheet is a top choice. It handles complex shapes well before steps like bending or punching.

Material Compatibility and Limitations

Types of Metals Used in Metal CNC Machining Processes

Metal CNC machining works with many metals:

-

Aluminum: Light and rust-resistant. Good for strong parts or pretty finishes.

-

Stainless Steel: Strong and doesn’t rust easily. Great for clean or tough environments.

-

Mild Steel: Affordable and strong. Used for building structures.

-

Brass: Easy to shape and conducts electricity well.

Yan Tai Deshibo supports these materials. They offer services like threading, countersinking, and reaming to make complete parts.

Materials Best Suited for Laser Cutting of Metal Sheets

Laser cutting of metal sheets works best with:

-

Stainless Steel: Cuts cleanly with nitrogen gas to prevent rust.

-

Aluminum: Needs strong lasers but gives great results when done right.

-

Mild Steel: Cuts easily with oxygen gas, which speeds up the process.

However, shiny metals like copper are harder to cut. They need special fiber lasers.

Applications Across Different Industries

Common Uses of CNC Machining in Industrial Fabrication

Metal CNC machining is used in many fields:

-

Electronics: Making cases with threaded holes.

-

Automotive: Building engine brackets.

-

Medical Devices: Crafting precise surgical tools.

-

Robotics: Creating custom frames with exact holes.

Yan Tai Deshibo offers more than just machining. They polish or sandblast parts to make them functional and attractive.

Where Laser Cut Steel Sheet is Preferred in Production

Laser cut steel sheet is popular for:

-

Architectural Panels: Decorative designs for buildings.

-

Control Cabinets: Precise cases for electronics.

-

Decorative Grilles: Artistic patterns for decor.

-

Prototyping: Quick designs for testing.

Its fast setup makes it great for small or large projects. At Yan Tai Deshibo, laser cutting of metal sheets fits into their full process. They cut, bend, weld, assemble, paint, or powder-coat parts to deliver complete solutions.

Cost, Efficiency, and Production Considerations

Comparing Operational Costs Between CNC and Laser Cutting

Both metal CNC machining and laser cutting of metal sheets are precise, but their costs differ:

-

CNC Machining:

Higher tool costs.

Slower for each part.

Best for thick materials or parts with internal features.

-

Laser Cutting:

Faster for thin sheets.

Quick setup.

Cheaper per part for flat shapes without extra steps.

Yan Tai Deshibo helps clients pick the right method. They consider project size, shape complexity, and material. They can also use both methods in one project if needed.

Evaluating Efficiency Based on Project Requirements

Efficiency isn’t just about speed. It includes reducing mistakes, saving material, and keeping operators involved. For example, laser cut steel sheet parts can go straight to bending if designed well. The design must consider the metal’s thickness for proper bending.

Similarly, machined parts can move to welding or powder coating smoothly. This happens when sizes are accurate across all steps. Yan Tai Deshibo’s all-in-one process ensures every step—from design to packaging—runs quickly and maintains quality.

Frequently Asked Questions (FAQ)

What is the main difference between metal CNC machining and laser cutting?

Metal CNC machining uses physical tools to cut or shape material through mechanical methods like drilling or milling. In contrast, laser cutting of metal sheets uses a light beam to melt or burn material without touching it. This makes laser cutting great for detailed work on thin metals.

Which method offers better precision?

Both are highly accurate. However, metal CNC machining often achieves tighter tolerances (±0.01 mm). It’s ideal for parts with internal features. Laser cut steel sheet is better for clean outer shapes with minimal rough edges.

Can I use both processes in one project?

Yes! For instance, a part might be cut with laser cutting of metal sheets and then machined for threads or holes. Yan Tai Deshibo combines both methods efficiently in their facility.

Is laser cutting more cost-effective than CNC?

For flat, thin sheets without complex features, laser cutting of metal sheets is usually faster and cheaper, especially for large batches. For thicker materials or parts needing depth, metal CNC machining may be more cost-effective over time.

What materials does Yan Tai Deshibo support?

They work with stainless steel, mild steel, aluminum, and brass. Their services include anodizing, painting, powder-coating, assembly, and packaging. This provides complete solutions tailored to your needs.

Interested in making custom metal parts efficiently? Contact Yan Tai Deshibo Metal Products Co., Ltd. today! They are your trusted partner for metal CNC machining, laser cutting of metal sheets, and full fabrication services—from design to delivery!