What Is Sheet Metal Fabrication?

Time : Jul 10, 2025 View : 738

Overview of Sheet Metal Fabrication

Definition and Core Processes of Sheet Metal Fabrication

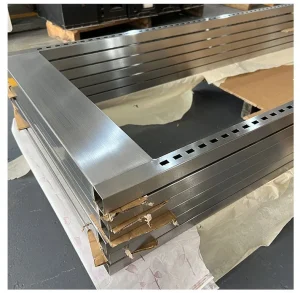

Sheet metal fabrication is a neat way to turn flat metal sheets into all kinds of shapes and stuff. You use tools to cut, bend, shape, weld, or stick pieces together. This makes parts for things like cars, planes, buildings, or even gadgets you use every day. It’s a big part of work in places like car shops, airplane factories, construction sites, and electronics companies.

Importance of Sheet Metal Fabrication in Modern Manufacturing

Sheet metal fabrication is really important because it can do so much. It makes parts that are light but super tough. That’s great for things like car bodies or kitchen stuff like fridges. Also, it lets people make special designs for whatever they need.

Key Processes in Sheet Metal Fabrication

Cutting Techniques in Sheet Metal Fabrication

Cutting is a huge step in sheet metal fabrication. There are cool ways to do it, like laser cutting, plasma cutting, or shearing. Laser cutting is really precise, so it’s awesome for fancy patterns. Plasma cutting is great for chopping through thick metal super fast. Shearing is good for making straight cuts on thin sheets. You pick the way based on what kind of metal you’ve got, how thick it is, and how exact you need the cut to be.

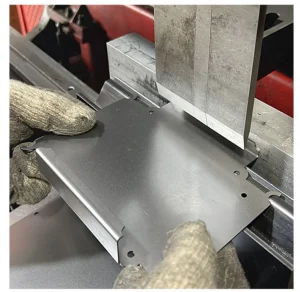

Bending and Forming Methods for Precision Metal Fabricators

Bending and shaping are key to making metal look the way you want. Machines called press brakes push the metal to make perfect angles. Another trick, roll forming, bends metal slowly into weird shapes, like tubes or curves. Precision metal fabricators use CNC machines for super accurate bends. These machines follow computer plans, so every bend comes out just right.

Welding and Assembly Procedures in Sheet Metal Finishing

Welding sticks metal pieces together to make one strong thing. You can use stuff like MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding because they make really solid connections.

Sometimes, you use rivets or bolts instead of welding. For sheet metal finishing, grinding makes welds smooth and nice. Adding paint or special coatings makes parts stronger and prettier.

Materials Used in Sheet Metal Fabrication

Common Metals: Stainless Steel, Mild Steel, and Aluminum

Stainless steel is super cool because it doesn’t rust and looks shiny. It’s used for kitchen tools or doctor’s equipment. Mild steel is easy to work with and doesn’t cost much. You see it in car frames or building materials.

Specialized Materials: Brass and Their Applications

Brass is a fancy metal that’s easy to shape and doesn’t rust. It’s got a gold-like look, so it’s great for decorations, like door handles or music instruments. It also carries electricity really well, so it’s used in wiring parts. Yan Tai Deshibo Metal Products Co., Ltd., is awesome at making custom sheet metal fabrication with these metals and CNC machining.

The Role of Precision Metal Fabricators

How Precision Enhances Manufacturing Efficiency

Precision metal fabricators make sure every piece is spot-on. This saves a ton of time and stops you from wasting metal. It also means you don’t have to fix mistakes later, which can cost a bunch. CNC machines help a lot because they do everything automatically and super exact. Cold tricks like stamping or punching make things fast without messing up the quality. These are perfect when you need to make lots of metal parts in a hurry.

Using CAD (Computer-Aided Design) software helps make really clear plans for parts. It makes sure picking the metal and putting it together matches what you wanted. Yan Tai Deshibo Metal Products Co., Ltd., uses these neat tools to build perfect parts for their customers.

The Importance of CAD Design in Precision Metal Fabrication

CAD design is a big deal for precision metal fabricators. It lets you see complicated shapes on a computer before you start cutting. This stops mistakes and saves metal, you know. Like, if you’re making a bracket with lots of bends, CAD figures out exactly how big each bend should be. That way, everything fits together perfectly when you’re done.

CAD also makes it easier for designers and workers to talk. They can share 3D pictures that are super clear, not like old flat drawings that can be confusing. Plus, CAD files go right into CNC machines. This makes going from planning to making stuff really quick and easy.

Yan Tai Deshibo Metal Products Co., Ltd., has great CAD design help. Their team works with customers to make parts that do their job and look good too.

Benefits of Outsourcing to Professional Precision Metal Fabricators

Streamlining the Manufacturing Process with End-to-End Solutions

Giving sheet metal fabrication to pros like Yan Tai Deshibo makes everything way simpler. They take care of it all, from getting the metal to sticking parts together. This lets you focus on stuff like inventing new products or selling them, while they handle the tough work.

Pro fabricators have awesome tools and people who know what they’re doing. They can cut, weld, grind, or do sheet metal finishing. For example, Yan Tai Deshibo uses CNC drilling for really exact holes and TIG welding for strong connections. They work with all sorts of metals, like stainless steel, aluminum, or brass, so they can do whatever you need.

Outsourcing also means you can make a little or a lot. Whether you want a few test parts or a huge batch, they’ve got you covered without any fuss.

How Outsourcing Supports Product Development and Marketing

Outsourcing to precision metal fabricators helps you make new stuff faster. With pros like Yan Tai Deshibo, you can try out designs quick with prototyping. This lets you test ideas and fix things in no time.

They also do extras like powder coating or anodizing. These make parts tougher and way nicer to look at. Pretty parts sell better because they stand out in stores or online.

Yan Tai Deshibo’s full package includes putting parts together into finished products ready to go. This saves you from dealing with a bunch of different companies. By letting them handle it, you can spend more time finding new buyers or making your brand bigger, which helps your business grow.

Frequently Asked Questions

What is sheet metal finishing?

Sheet metal finishing is when you add final touches to make parts look nice, last longer, or work better. Stuff like painting, anodizing, powder coating, polishing, or grinding gets it done.

Why is precision important in metal fabrication?

Precision makes sure parts fit together just right when you put them together. It saves metal and stops costly fixes. It also keeps everything high-quality every time.

How does Yan Tai Deshibo ensure high-quality fabrication?

Yan Tai Deshibo uses neat CNC machining tools and checks everything super carefully. From picking metal to the last look-over, they make sure it’s awesome.

What materials are commonly used in precision metal fabrication?

You usually see stainless steel for no rust, mild steel for cheapness, aluminum for light strength, and brass for fancy decorations.

Can outsourcing reduce manufacturing costs?

Yup, outsourcing saves money by cutting out the need for your own machines or big teams. Pros do sheet metal fabrication faster and better, so you spend less.

For custom sheet metal fabrication with cool tools like CNC machining or powder coating, get in touch with Yan Tai Deshibo Metal Products Co., Ltd., today!