The Ultimate Guide to Sheet Metal Fabrication

Time : Aug 07, 2025 View : 604

Overview of the Sheet Metal Fabrication Industry

Sheet metal fabrication is an important process. It changes flat metal sheets into useful items and parts. Many industries, like cars, airplanes, buildings, electronics, and energy, depend on it.

Key Applications Across Industries

Sheet metal parts are everywhere. In car-making, they build vehicle bodies and inner pieces. Airplanes use fabricated aluminum and titanium sheets because they are light but strong. In building work, sheet metal makes roofs, air ducts, and supports. Electronics companies use carefully cut sheet metal for cases and holders.

Common Materials Used in Fabrication

People often use aluminum, stainless steel, mild steel, galvanized steel, brass, and copper. Aluminum doesn’t rust easily and is light, so it’s good for many projects. Stainless steel is tough and doesn’t rust, making it great for medical or food items. Mild steel is cheap and easy to weld or shape.

Benefits of Sheet Metal Fabrication for Product Development

Sheet metal fabrication helps make prototypes fast. It also works for big production runs. Using CAD tools and CNC machines, detailed designs turn into exact parts. This process makes strong components with precise measurements while keeping costs down.

Core Processes in Sheet Metal Fabrication

Fabrication has several steps. Each step helps make the final product accurate, strong, and useful.

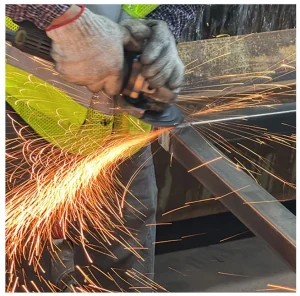

Cutting Techniques: From Laser to Industrial Flame Cutting

Cutting starts the process. It shapes raw sheets into usable pieces. The method depends on the material and its thickness:

- Laser cutting is very accurate and doesn’t damage the metal with heat.

- Waterjet cutting uses high-pressure water mixed with gritty materials. It makes detailed cuts without heat.

- Industrial flame cutting uses a torch with oxygen and fuel gases. It cuts thick carbon steel plates quickly. It’s perfect for big jobs like building beams or machine bases.

Sheet Metal Bending Process and Its Role in Shaping Components

The sheet metal bending process turns flat sheets into 3D shapes. It uses press brakes or folding machines. This process is key for making cases, brackets, frames, or channels. To get the right shape, the bend’s angle and curve must account for how the material springs back.

The Importance of Precision in Custom Sheet Metal Punch Operations

Custom sheet metal punch operations make holes or patterns. They use dies and high pressure. Punching ensures holes line up for screws or air vents in electronic cases. Custom punches create complex shapes faster than drilling.

Sheet Metal Welding for Structural Integrity and Assembly

Sheet metal welding joins parts into complete assemblies. It uses methods like MIG (CO2), TIG (argon), or spot welding:

- CO2 welding (MIG) is fast, cheap, and resists rust well.

- Ar welding (TIG) makes high-quality welds. It works on metals like aluminum or magnesium.

The weld’s quality affects the product’s strength and appearance. Yan Tai Deshibo Metal Products Co., Ltd. offers three weld finishes: C-grade (as-welded), B-grade (slightly smoothed), and A-grade (fully polished). These suit different needs.

Sheet Metal Bending Process: Techniques and Machinery

Press Brake Machines and CNC Control Systems

Modern press brakes use CNC systems. These control gauges, pressure, angles, and steps. This setup ensures the same results every time, even for large batches. Yan Tai Deshibo Metal Products Co., Ltd. uses CNC press brakes. They handle materials up to 6mm thick with steady accuracy.

Factors Influencing Accuracy in the Sheet Metal Bending Process

Several things affect bending accuracy:

- How thick the material is

- The direction of the metal’s grain

- The size of the die

- How much the material springs back

Using CAD software to test bends helps predict results before starting work.

Material Behavior During the Sheet Metal Bending Process

Materials act differently when bent. Designers must leave enough space between the structure and the bending die to avoid problems. For example:

- Aluminum can crack if bent too sharply.

- Stainless steel bounces back more.

To avoid cracks or wrinkles, designers pick the right bend radius based on the material.

Custom Sheet Metal Punch Solutions for Complex Designs

Types of Punching Machines Used in Modern Fabrication

Punching machines include:

- Mechanical turret punches

- Hydraulic presses

Yan Tai Deshibo Metal Products Co., Ltd. uses programmable punching systems. They create custom shapes without needing big tooling changes.

Optimizing Hole Patterns with Custom Sheet Metal Punch Techniques

Custom sheet metal punch techniques make vents, cable holes, or fastener spots. They keep parts strong. Punching mesh holes uses molds on standard or CNC machines. This is important for server racks or electronic cases, where cooling needs precise hole patterns.

Integrating Punching into Automated Production Lines

Punching can happen before bending or welding in automated lines. This cuts handling time and keeps batches consistent.

End-to-End Solutions from Design to Finishing

Yan Tai Deshibo Metal Products Co., Ltd. Customization Service handles everything from start to finish, all in one place.

CAD Design Support and Engineering Collaboration

Our experienced CAD designers help clients early on. They test things like bend allowances or punch gaps before making tools. We also take client sketches or drawings and turn them into formats our machines can use.

Full-Service Manufacturing: From Raw Material to Final Assembly

Our facility does it all: getting raw sheets, laser or flame cutting, sheet metal bending process, sheet metal welding, machining, surface treatment, packaging, and assembly. This lets clients focus on selling their products, not managing supply chains.

Frequently Asked Questions (FAQ)

What is industrial flame cutting used for?

It’s used in heavy industries like shipbuilding or construction. Thick carbon steel plates are cut efficiently, even if high precision isn’t needed.

What materials can be bent without cracking?

Most metals bend safely with the right radius. Aluminum needs a larger radius because it’s brittle. Mild steel and stainless steel are easier to bend if done right.

Can custom sheet metal punch create custom shapes?

Yes! Programmable turret punches or custom dies make complex patterns like logos, vents, or mounting features to match your design.

How do I choose between powder coating vs anodizing?

Powder coating is thicker and great for outdoor use. Anodizing protects aluminum with a thin, hard layer that keeps the metal’s look better than paint.

Does Yan Tai Deshibo offer design assistance?

Yes! We offer full CAD support, from simple sketches to detailed files, to ensure your parts are ready before production starts.

Ready to make your idea real? Contact Yan Tai Deshibo Metal Products Co., Ltd. today. We provide complete sheet metal fabricating solutions, including laser/flame cutting, CNC machining, sheet metal welding, and finishing services tailored to your needs!