The Top Benefits of Custom Metal Stamping You Need to Know

Time : Aug 21, 2025 View : 536

Why Custom Metal Stamping Is Essential in Modern Manufacturing

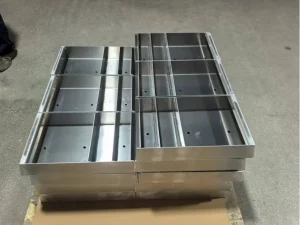

Custom metal stamping is a key part of today’s manufacturing. It uses special tools and machines to turn flat metal sheets into exact shapes. This method works well for making parts with tricky designs or tight measurements. It delivers steady, high-quality results every time.

The process involves steps like cutting, bending, or pressing metal. These steps create detailed pieces that stay the same size and shape. For businesses needing reliable parts in big numbers, this accuracy is vital.

Yan Tai Deshibo Metal Products Co., Ltd. uses top-notch techniques like punching, shaping, and deep drawing. These meet the needs of many industries. Their team of CAD designers and engineers helps fine-tune part designs early on. This saves time and ensures better quality from the beginning.

Applications Across Multiple Industries

Custom metal stamping is super flexible. It’s used in many fields because it can handle different tasks. In cars, it makes parts like supports and frame pieces. In electronics, it creates connectors and protective covers in large batches. Medical tools, like surgical gear and testing devices, also rely on stamped parts.

Thin metal sheets are easy to bend or shape using simple methods. This makes them great for building strong but light parts, useful in many areas.

Yan Tai Deshibo Metal Products Co., Ltd. serves various industries. They work with materials like stainless steel, mild steel, aluminum, and brass. They also offer finishes like powder coating or anodizing to fit specific project needs.

Key Advantages of Choosing Custom Metal Stamping Services

Enhanced Accuracy and Repeatability in High-Volume Production

Custom metal stamping is great at making thousands or even millions of matching parts. Each piece comes out nearly identical. This sameness is perfect for automated production lines where every part must fit just right. Yan Tai Deshibo uses CNC machines to ensure every piece meets exact standards.

Reduced Material Waste and Cost Efficiency

Unlike methods like CNC machining, stamping uses metal wisely. Tools are designed to cut sheets with little leftover scrap. This cuts costs, especially when making lots of parts.

Yan Tai Deshibo saves even more by offering services like cutting, shaping, welding, and assembly all in one place. This keeps costs low by avoiding extra shipping or handling fees.

Faster Turnaround Times for Complex Designs

Special tools, called dies, are made to match specific part shapes. Once ready, stamping creates complex pieces quickly. Tasks like cutting holes or adding details happen in seconds during each press.

Yan Tai Deshibo speeds things up with CAD software to check designs and make quick test parts. This gets projects done fast without losing quality.

How a Custom Metal Stamping Manufacturer Adds Value to Your Project

Design Support from In-House CAD Experts and Engineers

A good custom metal stamping manufacturer helps with design. Yan Tai Deshibo has CAD experts and engineers who improve your ideas. They turn rough sketches or detailed plans into designs that work well for production. This prevents costly fixes later on.

They use 3D modeling to build test parts before starting full production, ensuring everything is just right.

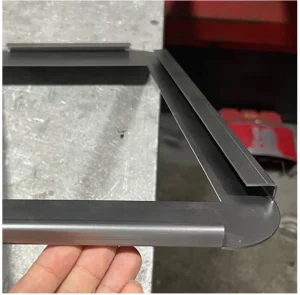

Flexibility in Material Selection and Finishing Options

Every project needs different material strengths or rust protection. Yan Tai Deshibo offers options like stainless steel for strength, aluminum for lightness, or brass for electrical use.

They also provide finishes like anodizing to stop rust, powder coating for style, painting, brushing, polishing, spraying, silk-screen printing, or electroplating. These make parts both useful and good-looking.

Scalable Production Capabilities for Varying Order Sizes

Whether you need 50 test parts or 50,000 finished pieces each month, Yan Tai Deshibo can do it. Their workshop has CNC machines for small jobs and big presses for large orders.

This range helps everyone, from small startups to huge companies, as they move from early testing to full product launches.

Comparing Custom Metal Stamping with Other Fabrication Methods

Differences Between Stamping, Laser Cutting, and CNC Machining

Stamping, laser cutting, and CNC machining all shape metal, but each works differently:

Stamping uses tools and pressure to make shapes fast. It’s best for big batches.

Laser cutting is flexible, needing no tools, but it’s slower for each piece.

CNC machining cuts metal with tools for great accuracy but takes longer and costs more.

Stamping shines for repeated parts in large amounts. Once tools are set, each part takes only seconds.

Yan Tai Deshibo mixes these methods cleverly. They use laser cutting for test parts or detailed designs, CNC machining for precise holes or turns, and stamping for big production runs. This gives clients the best mix for their project.

When to Choose Stamping Over Alternative Processes

Go with custom metal stamping if:

You need thousands of matching parts.

Your design has repeated features like holes or bends.

You want lower costs per part after making the tools.

Speed matters more than changing designs once production starts.

For tasks like punching holes or bending, stamping is quicker than manual methods. Yan Tai Deshibo’s automated systems make it even faster.

The Importance of Partnering with the Right Custom Metal Stamping Manufacturer

What to Look for in a Reliable Manufacturing Partner

Pick a partner who offers:

Experience in different industries.

Clear talks during pricing and design steps.

Strong checks to ensure parts are accurate.

Extra services like welding, riveting, or grinding.

Yan Tai Deshibo stands out with quality checks at every stage, from testing raw materials to checking final parts against your needs.

Benefits of End-to-End Solutions from a Single Provider

Using one company from start to finish simplifies things. Yan Tai Deshibo handles everything: cutting metal, bending, welding, finishing, assembling, and packing—all in one spot.

This saves time and keeps everything on track. It avoids problems that can come from working with multiple suppliers.

Yan Tai Deshibo Metal Products Co., Ltd. Customization Service

Long-Term Benefits of Investing in Custom Metal Stamping Services

Improved Product Consistency and Brand Reputation

Matching parts build trust. Stamped pieces stay nearly the same every time, ensuring products work well right away. This leads to happy customers and a strong brand over time.

Yan Tai Deshibo’s careful checks, like measuring parts after stamping, stop issues that could hurt performance later.

Streamlined Supply Chain Management Through Outsourcing

Dealing with many suppliers is tough. By letting Yan Tai Deshibo handle design and production, you can focus on creating and selling your product. They manage everything, from getting materials to packing parts for shipping.

They work like part of your team, not just another supplier.

FAQ Section

What materials can be used in custom metal stamping?

You can use stainless steel, aluminum, mild steel, brass, copper alloys, or special metals depending on the job. Yan Tai Deshibo offers solutions tailored to strength or environmental needs.

How does custom metal stamping reduce costs?

After tools are made, stamping makes parts fast with little waste. This is cheaper than machining or 3D printing for big runs. Smart cutting layouts also save material.

Can I order both prototypes and mass production from the same provider?

Yes. Yan Tai Deshibo makes small test batches with laser cutting or CNC machining and large runs with stamping presses, all in one place.

What types of finishes are available after stamping?

Finishes include powder coating, anodizing, electroplating, silk-screen printing, brushing, and polishing. These improve looks and protect parts based on their use.

Why choose Yan Tai Deshibo over other manufacturers?

They provide full services, from CAD design to final assembly, with steady quality. Their skills in sheet metal work and CNC machining help many industries, making them a reliable partner for growing projects.

Ready for a faster project with fewer issues? Reach out to Yan Tai Deshibo Metal Products Co., Ltd. today. Every stamped part they make comes with precision and dependability!