Springback in Sheet Metal Bending: How to Predict and Compensate

Time : Oct 23, 2025 View : 291

Introduction

What is Sheet Metal Springback?

Sheet metal springback happens when a bent piece bounces back slightly after the bending force gets removed. It’s that elastic recovery. The metal tries to return to its original shape. Simple as that.

Why Springback Matters in Metal Fabrication

Springback can mess up tolerances and lead to parts that don’t fit right. In fabrication, accuracy is key. Ignoring it means rework, higher costs, and delays. Fabricators deal with this daily.

Common Industries Affected by Springback (Automotive, Aerospace, Appliances)

Automotive parts like brackets need precise bends to avoid assembly issues. Aerospace demands tight tolerances for safety. Appliances, think enclosures, suffer if panels warp. These sectors feel the pinch most.

Factors Influencing Springback

Material Properties: Elasticity, Yield Strength, and Thickness

Materials with high elasticity spring back more. Yield strength plays a role too; lower yield means easier bending but bigger recovery. Thickness matters a lot. Thinner sheets, say under 2mm, show more springback. From design guides, the ratio of inner bend radius to thickness affects it hugely. Larger ratios lead to bigger springback.

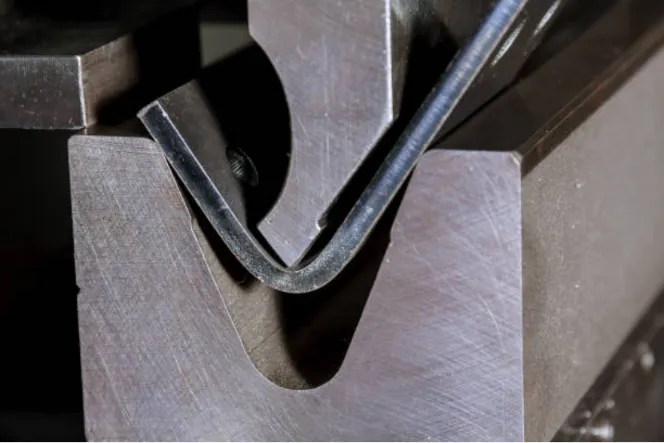

Bending Method: Air Bending vs Bottoming vs Coining

Air bending lets the metal float, causing more springback. Bottoming presses the sheet fully into the die, reducing it some. Coining crushes the material, minimizing recovery almost to zero. But coining wears tools faster. Choose based on the job.

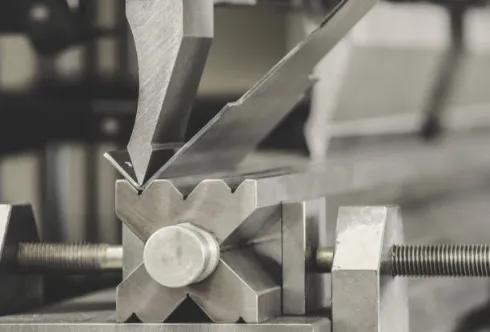

Die Geometry and Bend Radius

Sharp dies increase stress, boosting springback. A larger bend radius cuts it down. Residual stresses build up in tight bends. In practice, for steel, keep radius at least equal to thickness to avoid cracks.

Temperature and Residual Stresses

Heat the metal, and springback drops because elasticity changes. But room temp bending is common. Residual stresses from prior cuts or welds add to the problem. Sometimes, annealing helps, but that’s extra steps.

How to Predict Springback

Calculating Springback Using Formulas and Bend Allowance

Start with basic formulas.

Springback angle ≈ (3 * bend angle * radius) / (elastic modulus * thickness^3).

Better use bend allowance: length = π * (radius + K * thickness) * (angle/180).

K factor adjusts for material. For stainless, K is around 0.33. Test bends help refine.

Using Simulation Tools: CAD and Finite Element Analysis (FEA)

CAD software like SolidWorks simulates bends. FEA digs deeper, modeling stresses. Input material data, and it predicts recovery. Saves trial and error. Many shops swear by it for complex parts.

Predicting Springback in Aluminum and Steel

Take aluminum enclosures. With low yield, springback hits 2-3 degrees on a 90-degree bend. Simulations nailed it, adjusting overbend by 3 degrees. For steel brackets, thickness 1.5mm, FEA showed 1 degree recovery. Real tests matched. In one case, from old docs, a U-shape steel part warped due to ignored residuals. Fixed with better radius.

Some old design manuals stress mechanical properties like wall thickness and radius. They note bigger radius-to-thickness ratios amp up springback. Spot on for steel vs aluminum.

Compensation Techniques

Overbending: Pre-Bending to Offset Springback

Bend a bit extra. If springback is 2 degrees, aim for 92 on a 90-degree target. Easy fix. But measure first. Works great for air bending.

Bottoming and Coining Methods to Reduce Springback

Bottoming forces the sheet down, cutting springback by half sometimes. Coining eliminates it but needs tons of force. For precision, like ±0.5° accuracy in CNC services, coining shines on brackets.

Tooling Adjustments: Custom Dies and Punch Shapes

Custom dies with variable radii help. Adjust punch angle slightly. In multi-bends, sequence matters to avoid interference. Old cases show narrow bends cause cracks if not adjusted.

Process Optimization: Adjusting Bend Speed and Force

Slow bends reduce springback. Higher force in bottoming helps too. Optimize pressure; too much distorts. In docs, positive pressure during bending cuts recovery. Add ribs in bend zones to stiffen and suppress it.

Quality Control and Verification

Measuring Bend Angles and Deformations

Use angle gauges or CMMs. Check after each bend. Deformations show in multi-bends. Laser scanners catch tiny shifts.

Correcting Deviations in Multi-Bend Parts

For Z-shapes, fix one bend, then adjust next. If off, rebend carefully. In cases, U and Z profiles need spatial ribs to fight instability.

Reducing Scrap and Improving Manufacturing Consistency

Track data from runs. Consistent materials cut variability. Better prediction means less waste. Shops report 20% scrap drop with good comp.

Best Practices for Sheet Metal Fabricators

Selecting the Right Materials and Thickness

Pick low-elasticity alloys. For steel, Q235 works well. Thickness over 1mm helps. Avoid thin if possible.

Maintaining Press Brake Tools for Precision

Clean dies regular. Worn tools spike springback. Sharpen punches. It’s basic but overlooked sometimes.

Leveraging Software Simulation Before Production

Run FEA pre-prod. Catches issues early. For complex, like deep draws, sims predict thickness changes too. Worth the time.

Conclusion

Recap: Why Predicting and Compensating Springback Is Critical

Springback throws off accuracy. Predict with tools, compensate smartly. Keeps parts fitting, costs down.

How Deshibo Helps Clients Achieve Accurate Bends

Deshibo, a sheet metal fab expert, uses advanced CNC for ±0.5° bends. Their services handle stainless, aluminum, with custom comp for springback. Clients get precise brackets, enclosures.

Encouraging Knowledge-Based Decision Making in Metal Fabrication

Base choices on data, not guesswork. Study materials, test bends. Leads to better fab every time.

FAQ

Q1: What causes the most springback in sheet metal?

High elasticity and small bend radii top the list. Thinner materials make it worse.

Q2: Can springback be completely eliminated?

Not always, but coining gets close. Overbending handles the rest.

Q3: How does temperature affect springback?

Warmer metal reduces it. But most bends happen at room temp.

Q4: What’s the best tool for predicting springback?

FEA software. Accurate for aluminum and steel cases.

Q4: Why add ribs to bends?

They boost stiffness, cutting recovery. From design norms, it suppresses rebound effectively.