Laser Cutting and Bending: How Do They Affect Each Other?

Time : Jun 26, 2025 View : 788

The Relationship Between Sheet Metal Laser Cutting and Bending

How Sheet Metal Laser Cutting Works and Affects Metal

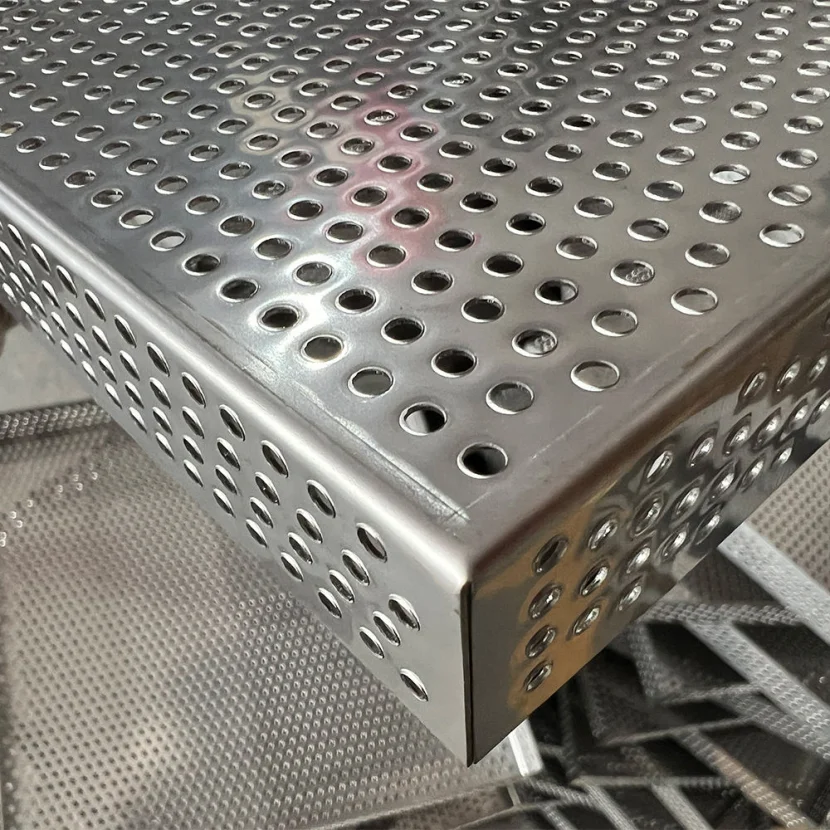

Sheet metal laser cutting is a cool way to shape metal with a super strong laser beam. The laser focuses on the metal and melts or burns it to make clean cuts. It’s great because it can create tricky shapes and patterns without messing up the rest of the metal.

When the laser cuts, it heats the metal a bit around the edges. This heated spot is called the Heat-Affected Zone, or HAZ. It’s pretty small compared to old-school cutting, but it can still change how the metal acts later. For example, it might affect CNC bending services. Sheet metal laser cutting makes neat cuts, so there’s less waste. This helps make building stuff faster and better.

How Sheet Metal Laser Cutting Helps CNC Bending Services

The neat cuts from sheet metal laser cutting make CNC bending services work better. When the edges are smooth and exact, the metal fits perfectly in bending machines. This cuts down on mistakes when bending. Smooth edges line up nicely with the bending tools. As a result, you get perfect angles and shapes every time.

Plus, custom laser cut sheet metal needs fewer tweaks during bending. This saves time and makes work go quicker. The teamwork between sheet metal laser cutting and bending creates awesome results for tricky metal projects.

Picking the Right Metal for Sheet Metal Laser Cutting and Bending

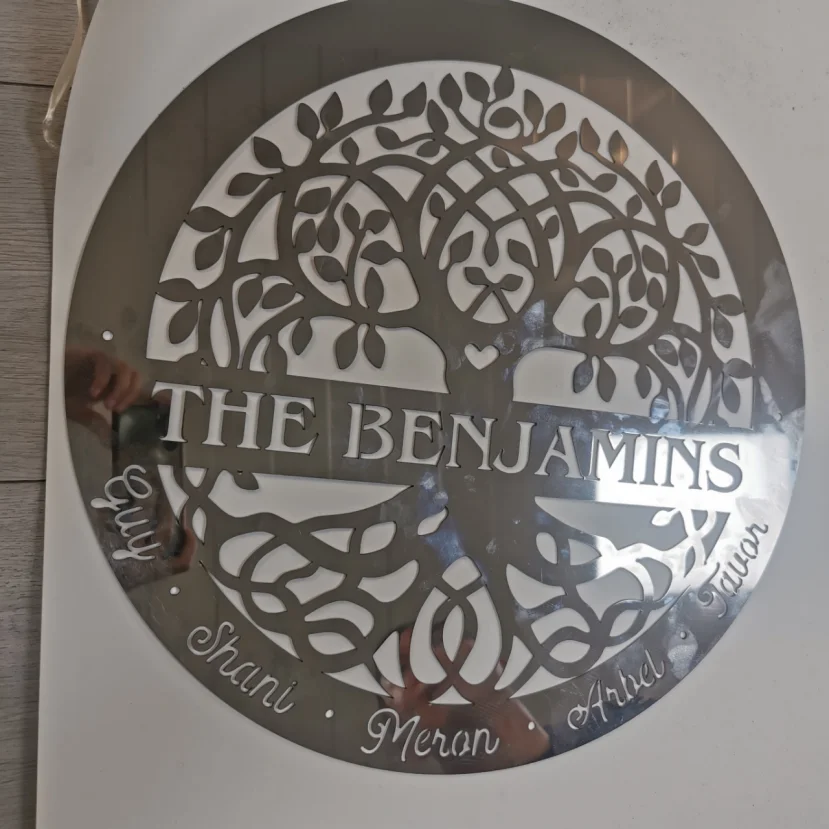

Choosing the right metal is super important for sheet metal laser cutting and bending. Metals like stainless steel, aluminum, and mild steel are popular because they work well with both steps. Each metal acts a bit different when heated by the laser, which can change how it bends later.

For example, stainless steel stays strong even after getting hot. It’s great for stuff that needs to last. Aluminum is light and easy to shape, perfect for fancy designs. But you gotta be careful with it to avoid squishing it. Picking the right metal helps make all kinds of parts using simple methods.

What Connects Sheet Metal Laser Cutting and Bending

How Heat-Affected Zones Affect Metal Work

The Heat-Affected Zone (HAZ) is a big deal in sheet metal laser cutting and bending. When the laser cuts, it heats the metal near the edges. This heat can change the metal’s structure a tiny bit. Even though the HAZ is small in modern lasers, it can affect how the metal bends later.

If you don’t handle it right, the HAZ might cause cracks or wonky bends in some metals. To avoid this, workers adjust things like laser power or speed. This keeps the HAZ small and makes sure the metal bends nicely.

How Cut Quality Affects Bending Accuracy

The quality of cuts from sheet metal laser cutting really matters for CNC bending services. If the edges are rough or have burrs, they won’t line up right in the bending machine. This can lead to messy bends or uneven shapes.

Yan Tai Deshibo Metal Products Co., Ltd. uses neat tricks, like smoothing edges after cutting. This helps custom laser cut sheet metal work perfectly during bending. Good cuts mean better bends, simple as that.

Why Smooth Edges Are Key for Great Bending

Smooth edges are super important for sheet metal laser cutting and bending to work together. When edges are nice and smooth, they slide easily against bending tools. This stops scratches or dents from happening during bending.

Smooth edges let workers make big parts quickly while keeping everything top-notch. It’s a big part of making sure the whole process goes smoothly.

Making Sheet Metal Laser Cutting and Bending Work Better Together

Ways to Stop Metal from Warping During Laser Cutting

Sheet metal laser cutting is a precise way to shape metal, but the heat can sometimes mess things up. To keep metal from warping, workers control stuff like laser power, speed, and focus. They also use helper gases, like nitrogen or oxygen, to make cuts cleaner and stop rust.

Another trick is warming the metal a bit before cutting. This cuts down on stress that could hurt the metal. Yan Tai Deshibo Metal Products Co., Ltd. uses top laser machines that keep the HAZ tiny. This keeps custom laser cut sheet metal in great shape for CNC bending services.

Tweaking CNC Bending for Laser-Cut Metal

CNC bending services depend a lot on how the custom laser cut sheet metal turns out. Things like metal thickness, edge smoothness, and leftover stress from cutting decide how to set up the bending machine. For example, thin metal needs less force to bend so it doesn’t crack or warp.

Workers also adjust the bending angle based on how strong the metal is. This makes sure every project comes out right. Yan Tai Deshibo Metal Products Co., Ltd. uses computer programs, like CAD software, to plan these settings before starting. This makes bending super accurate.

Top Tips for Mixing Cutting and Bending

Getting sheet metal laser cutting and bending to work together smoothly is key for fast work. One great tip is to keep edges super smooth after cutting. This makes it easy for the metal to line up with bending tools.

Using guides or templates during bending also cuts down on mistakes from bad alignment. Yan Tai Deshibo Metal Products Co., Ltd. offers complete solutions. They use edge-smoothing tricks and custom guides to make production fast and keep quality high.

Challenges in Mixing Sheet Metal Laser Cutting and Bending

Problems from Bad Teamwork Between Steps

If sheet metal laser cutting and CNC bending services aren’t planned well together, things can go wrong. You might get bends that don’t line up, angles that aren’t right, or even metal that breaks. These issues often come from cuts that aren’t exact or stress left over from cutting.

To fix this, workers need to talk clearly between design and machine teams. Using computer programs that connect cutting and bending helps a lot. It keeps everything on track and avoids mess-ups.

Dealing with Stress from Cutting and Bending

Doing sheet metal laser cutting and then bending can add stress to the metal. This stress might hurt how the metal works in the end. For example, too much heat from cutting can change metals like aluminum or stainless steel. This makes them more likely to crack when bending.

To handle this, Yan Tai Deshibo Metal Products Co., Ltd. uses stress-relief tricks, like annealing, after cutting but before bending. Annealing helps calm the metal down. This makes it stronger and better for the final product.

Frequently Asked Questions

How does metal thickness affect CNC bending services?

Thicker metals need more force and bigger tools to bend without cracking or warping.

What can stop metal from warping during sheet metal laser cutting?

Adjusting laser power, using gases like nitrogen, and warming metal beforehand help keep it from warping.

Why are smooth edges important for sheet metal laser cutting and bending?

Smooth edges make metal line up better with bending tools. This stops scratches and damage during bending.

Can stress from sheet metal laser cutting mess up CNC bending accuracy?

Yup, leftover stress can cause uneven bends or cracks. Stress-relief tricks like annealing fix this.

What makes Yan Tai Deshibo Metal Products Co., Ltd. special?

They offer full solutions with CAD design, precise sheet metal laser cutting, smooth CNC bending services, and extra finishing like painting or powder coating.

Yan Tai Deshibo Metal Products Co., Ltd. is great at sheet metal work. They make high-quality parts tailored to your needs. Contact them today to learn about their awesome manufacturing skills!