How to Stop Peeling After Nickel or Chrome Plating

Time : Nov 07, 2025 View : 216

Introduction: When Plating Starts to Fail

Peeling or flaking in metal plating is a real headache. The shiny nickel or chrome layer starts lifting off the base metal, leaving a rough, blotchy surface. It ruins the part’s look, weakens its protection against rust, and makes it less dependable. Nobody wants a product that looks like it’s falling apart. Deshibo, a skilled sheet metal manufacturer, tackles this by focusing on solid prep work and strict process control to make sure plating sticks tight.

Why Nickel or Chrome Plating Peels Off

Poor Surface Preparation

If the base metal isn’t clean, the plating won’t hold. Oil, grease, rust, or oxides act like a shield, blocking the coating from sticking. Think of it like taping a dirty plate, it just peels off. Proper cleaning and degreasing are must-dos. Skip these or rush through, and you’re asking for trouble. Even a speck of dirt can mess things up big time.

Improper Pre-Treatment or Activation

Getting the surface ready is super important. Without it, the coating won’t grip right. Acid pickling or a strike layer (a thin first coat) preps the metal, giving it a texture for the plating to grab. Mess this up, like using weak acid or skipping the strike, and peeling’s almost guaranteed. It’s like painting without primer; the top layer just slides off.

Incorrect Plating Parameters

Plating’s a tricky process. The bath needs to be spot-on. Temperature, current, or chemical mix can make or break how well the plating sticks. Too hot or too cold, and the coating might come out weak. Wrong current? It could be brittle or spotty. Deshibo’s workshops avoid these slip-ups by keeping tight control and checking bath conditions often. A tiny mistake can lead to a whole batch flaking later.

Material Compatibility Issues

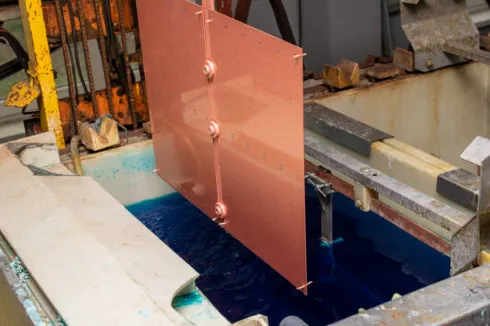

Not every metal gets along with nickel or chrome. Aluminum or zinc die cast, for example, need extra steps like a copper underlayer to hold the plating. Without it, the layers split apart. It’s like trying to glue plastic to glass, won’t work without the right prep. Picking the wrong underlayer or skipping it is a big reason for peeling.

How to Prevent Peeling in Nickel or Chrome Plating

Ensure Thorough Cleaning and Surface Activation

Prep work’s half the job. Here’s the deal: degrease to clear out oils, dip in acid to clean and wake up the surface, rinse to wash away leftover stuff, then add a strike layer for better sticking. Every step counts. Baths need regular checks to stay clean. A quick water break test (water should spread smooth on a clean surface) shows if the metal’s ready. Skimp here, and the plating’s toast from the get-go.

Optimize Bath Composition and Process Control

The plating bath’s a delicate thing. Temperature, pH, and current need to stay just right. Too much change, and the coating might be flimsy or uneven. Real-time monitoring keeps things steady. Deshibo’s team, for example, tracks data to make sure every batch is solid. It’s not a set it and forget it deal, small tweaks keep the bath on point. A steady process means fewer problems down the road.

Use Proper Underlayers

For tough metals like aluminum or zinc, a copper or nickel strike layer is a lifesaver. These underlayers act like a bridge, helping the topcoat stick and fighting rust better. Multilayer setups aren’t just for sticking; they keep parts safe from corrosion longer. Think of it like building a house, you need a strong base before the walls. Picking the right underlayer for the metal is key to stopping peeling.

Regular Quality Testing

Testing spots trouble early. Simple checks, like the tape test (stick tape on, pull it off, see if plating lifts) or bend tests (bend the part to check for cracks), catch issues fast. Salt spray tests show how well the plating fights rust. Catching a bad batch early saves time and cash. Nobody wants to toss a whole run of parts over something fixable.

Best Practices from Plating Experience

One time, a client had parts peeling ‘cause the cleaning wasn’t good enough. By beefing up the degreasing and adding a stronger acid step, the problem vanished. The big takeaway? Great plating starts way before the tank. It’s about nailing the prep, keeping the bath in check, and testing every step. Cutting corners just leads to rework and grumpy customers. Deshibo treats every batch like it’s the only one.

Sometimes, little stuff causes big issues. A rushed rinse between cleaning steps can leave gunk that wrecks adhesion. Or a bath with a slightly off pH can make the coating weak. These fixes ain’t fancy, but they matter a ton. Good plating’s about sticking to the plan, not taking shortcuts.

Conclusion

Peeling in nickel or chrome plating usually comes from a few slip-ups: messy prep, off target bath settings, or mismatched metals. Stopping it is better than fixing it. Spend time on solid cleaning, proper activation, and tight process control, and you’ll see results. Durable, shiny plating isn’t rocket science, it’s just doing things right. With years of know how in metal finishing, Deshibo helps clients get tough, flawless plated parts that last.

FAQ

Q: Why does chrome plating peel more often than nickel?

A: Chrome’s a harder, thinner layer that leans hard on underlayers like nickel to stick. If prep or the underlayer’s off, chrome’s more likely to flake.

Q: Can peeling be fixed without replating?

A: Nope, not really. Once peeling starts, the coating’s shot. Stripping and replating with proper prep is usually the only way to go.

Q: How often should plating baths be tested?

A: Daily checks for pH, temperature, and gunk are best. Weekly or per batch tests for adhesion and rust resistance catch problems early.

Q: Is peeling always the plater’s fault?

A: Not always, but mostly. Design flaws, like sharp edges or bad material picks, can play a part. Still, most peeling comes from process goofs, like weak cleaning or wrong settings.