How to Choose the Best Custom Sheet Metal Laser Cutting Service for Precision Manufacturing

Time : Sep 11, 2025 View : 452

Introduction

If you are an engineer, a buyer in manufacturing, or someone trying to turn a design into a real product, you probably know the headache of choosing the right metal fabrication partner. There are hundreds of suppliers out there. Some promise everything, but when the parts arrive, tolerances are off, or delivery is late. Others are cheap upfront, but hidden costs show up later. That’s where the question becomes critical: How to Choose the Best Custom Sheet Metal Laser Cutting Service for Precision Manufacturing?

This article walks through the key factors to evaluate before committing to a supplier. Along the way, we will share practical examples, industry details, and what experienced manufacturers actually check when they outsource metal fabrication.

Why Laser Cutting Has Become the Go To Method

Laser cutting has taken over a huge share of the metal fabrication market. Why? A few reasons stand out:

Accuracy: Modern CNC laser systems can achieve tolerances as tight as ±0.1mm.

Speed: Cutting complex shapes in minutes instead of hours.

Flexibility: Works on stainless steel, aluminum, carbon steel, and even copper with fiber lasers.

Clean Finish: Less post processing needed compared to plasma or mechanical cutting.

Think about producing a batch of stainless brackets. In traditional punching, the edges need heavy deburring. With laser cutting, edges come smooth and ready for the next step, whether that’s bending, welding, or coating.

Key Factors to Consider When Choosing a Sheet Metal Laser Cutting Partner

1. Precision and Tolerance Capabilities

When dealing with high performance industries like aerospace or electronics, even 0.2mm can make a part unusable. A reliable service provider should clearly state their minimum tolerance levels. Look for:

±0.1mm or ±0.2mm standard tolerance range

Consistency proven by sample reports

Use of CAD/CAM integration to avoid data loss between design and cutting

2. Industry Experience

Experience matters in metal fabrication. A supplier with 15+ years of OEM projects has likely handled thousands of unique requests. They’ve seen the tricky geometries, thin aluminum sheets that warp under heat, and structural steel plates that require heavy bending after cutting.

For instance, Yan Tai Deshibo Metal Products Co., Ltd. has specialized in sheet metal manufacturing and CNC machining for over a decade, providing end-to-end metal solutions from laser cutting and bending to welding and powder coating. That breadth of experience means fewer surprises for the client.

3. Delivery Time and Flexibility

Even the best part loses value if it arrives late. Delivery capacity is often underestimated during supplier selection. When comparing partners, ask:

What is their standard lead time? (10-15 working days is a common baseline)

Do they offer expedited production in urgent cases?

What is their on time delivery rate?

One real world example: a construction equipment manufacturer needed prototype enclosures in under two weeks. The supplier who could adapt and fast track production won the contract, even though their unit price was slightly higher.

4. Certifications and Quality Systems

Certifications may sound boring, but they matter when you’re supplying to regulated industries. A partner that follows ASME or ISO standards can provide the material certificates, RoHS/REACH compliance, and 3D inspection reports buyers expect.

This not only builds trust but reduces risks during audits or customer inspections.

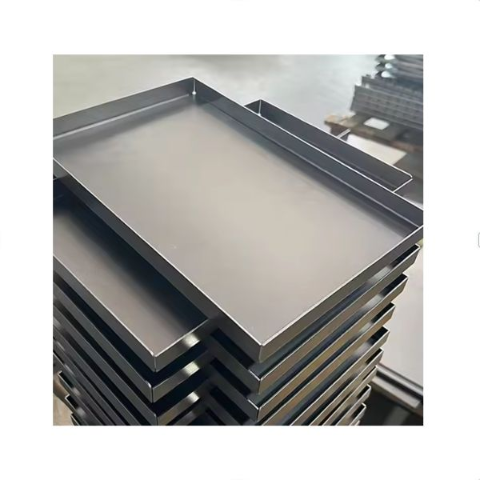

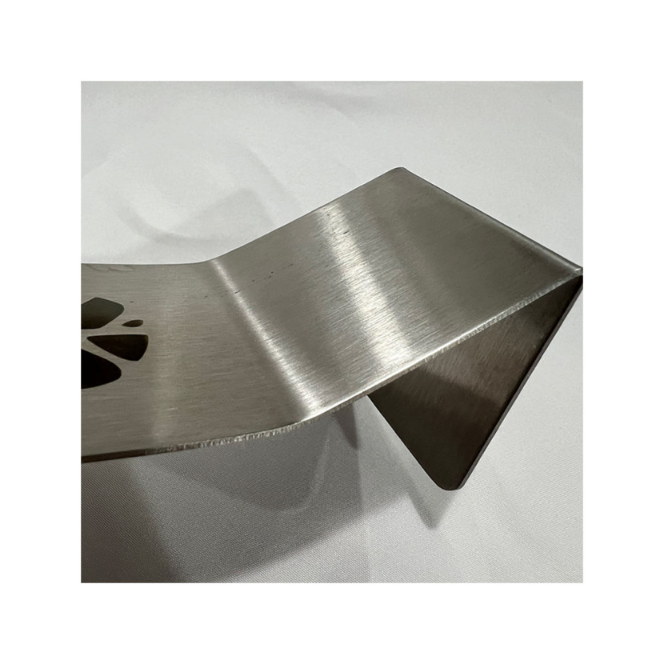

5. Range of Services Beyond Cutting

Laser cutting alone is rarely enough. After cutting, you may need bending, TIG welding, powder coating, or surface finishing. Working with a single vendor that offers the whole chain saves time and prevents mistakes during subcontracting.

At Deshibo, for example, customers often order custom sheet metal laser cutting together with bending and surface finishing, getting a complete part instead of just flat blanks. Deshibo also provides customized DFM support to improve manufacturability.

Practical Checklist Before You Decide

When selecting a manufacturing partner, ensure they meet key criteria: maintain tight tolerance capabilities of ±0.1mm to ±0.2mm for precise assembly fit; have over 10 years of experience with OEM references to minimize errors; offer delivery in 10-15 days with expedited options to keep projects on track; hold certifications like ASME, RoHS, and REACH with QC reports to avoid compliance issues; provide full services including cutting, bending, welding, and finishing for efficiency; and assign a dedicated account manager for clear, real time communication to prevent delays and miscommunication.

Use this table not just as a theory but as a conversation tool when speaking with suppliers.

Real Scenarios Where the Right Partner Makes a Difference

Electronics Housing: A thin aluminum housing required intricate vents. Laser cutting with ±0.1mm tolerance avoided the bending distortion that often happens with mechanical punching.

Automotive Brackets: Stainless steel brackets needed both strength and clean surface finishing. One stop fabrication with cutting, TIG welding, and powder coating reduced total cost.

Construction Panels: Large galvanized steel panels were delivered on a tight timeline for a building project. A supplier with flexible production scheduling secured repeat orders.

These are not just numbers on paper. They represent costly mistakes avoided by picking the right fabrication partner.

Conclusion

Choosing the best custom sheet metal laser cutting service is not about chasing the lowest price. It’s about finding a partner that balances precision, experience, delivery reliability, and certification. A good choice saves time, reduces rework, and builds a stronger supply chain for the future.

Yan Tai Deshibo Metal Products Co., Ltd. continues to support clients worldwide with reliable, certified, and custom sheet metal fabrication services, making complex ideas manufacturable at scale.

FAQs

Q1: What makes a custom sheet metal laser cutting service suitable for precision manufacturing?

A1: Custom sheet metal laser cutting service offers high precision tolerances of ±0.1mm to ±0.2mm, ensuring precise part fit.

Q2: How do I compare different sheet metal laser cutting suppliers?

A2: Compare tolerance ranges, delivery times, certifications, and communication style. A detailed sample or pre production part is often the best test before committing to mass production.

Q3: Can custom sheet metal laser cutting reduce overall manufacturing costs?

A3: Yes. Precision cutting reduces waste, smooth edges cut down on post processing, and one stop services like bending and welding eliminate subcontracting delays.

Q4: Why are fiber lasers often recommended for custom sheet metal fabrication?

A4: Fiber lasers are especially effective for reflective metals like aluminum and copper, offering faster speed and cleaner cuts compared to CO2 systems.

Q5: How fast can I expect delivery from a professional sheet metal laser cutting service?

A5: Standard lead time is usually around 10-15 working days. Some companies also offer expedited services depending on project urgency.