How Gas Selection Affects Laser Cutting Quality in Sheet Metal Production

Time : Sep 19, 2025 View : 416

Laser cutting has changed the way sheet metal parts are made. You can use a very focused beam. With it, you cut tricky shapes out of carbon steel, stainless steel, or aluminum. The cuts are exact, down to ±0.1 mm. But the key to nice edges and smooth ends is not only the laser. The kind of help gas you pick, like oxygen, nitrogen, or even plain air, makes a big difference in cut looks, speed, and price. Before we look at how gases help, let’s talk about a good friend in this work.

Deshibo has more than twenty years of sheet metal expertise, delivering ISO certified fabrication services across over 300 material grades. The company specializes in laser cutting, handling stainless steel from 0.5 mm to 30 mm, aluminum alloys from 1 mm to 25 mm, and carbon steel up to 40 mm. Their laser systems achieve ±0.05 mm positioning accuracy with a focal spot diameter of just 20 μm. Add to that instant quoting, no minimum order requirements, and full RoHS/REACH compliance, and you can see why many buyers choose them as a long term partner. If you are exploring a reliable solution provider, it is worth checking their services and company background.

What Role Does Gas Play in Laser Cutting?

Help gases do more than push away melted metal. They change how the laser works with the stuff. Various gases alter the mix at the cut spot. This touches edge looks, heat put in, and cutting pace. For instance, oxygen mixes with carbon steel. It makes more heat. This lets the laser go quicker. On the other hand, nitrogen gives a safe cover. It keeps stainless steel edges shiny and free of rust. Plain air, a cheap pick, is often used when edge looks do not matter much.

The choice hangs on material kind, how thick it is, and the edge looks you want. Thin stainless steel for seen panels often gets better with nitrogen. Thick carbon steel frames may like oxygen for faster work.

How Does Oxygen Affect Carbon Steel Cutting?

When you cut carbon steel, oxygen is the usual pick. It mixes with the steel. This makes a hot reaction that adds warmth and lifts cutting work. So, you get quicker speeds. You can handle thicker plates too. Yet, there is a swap. You might get rust. Edges may look dark. Extra junk can stick if gas push is not right. For building parts where outside looks are not key, oxygen is often the cheapest way.

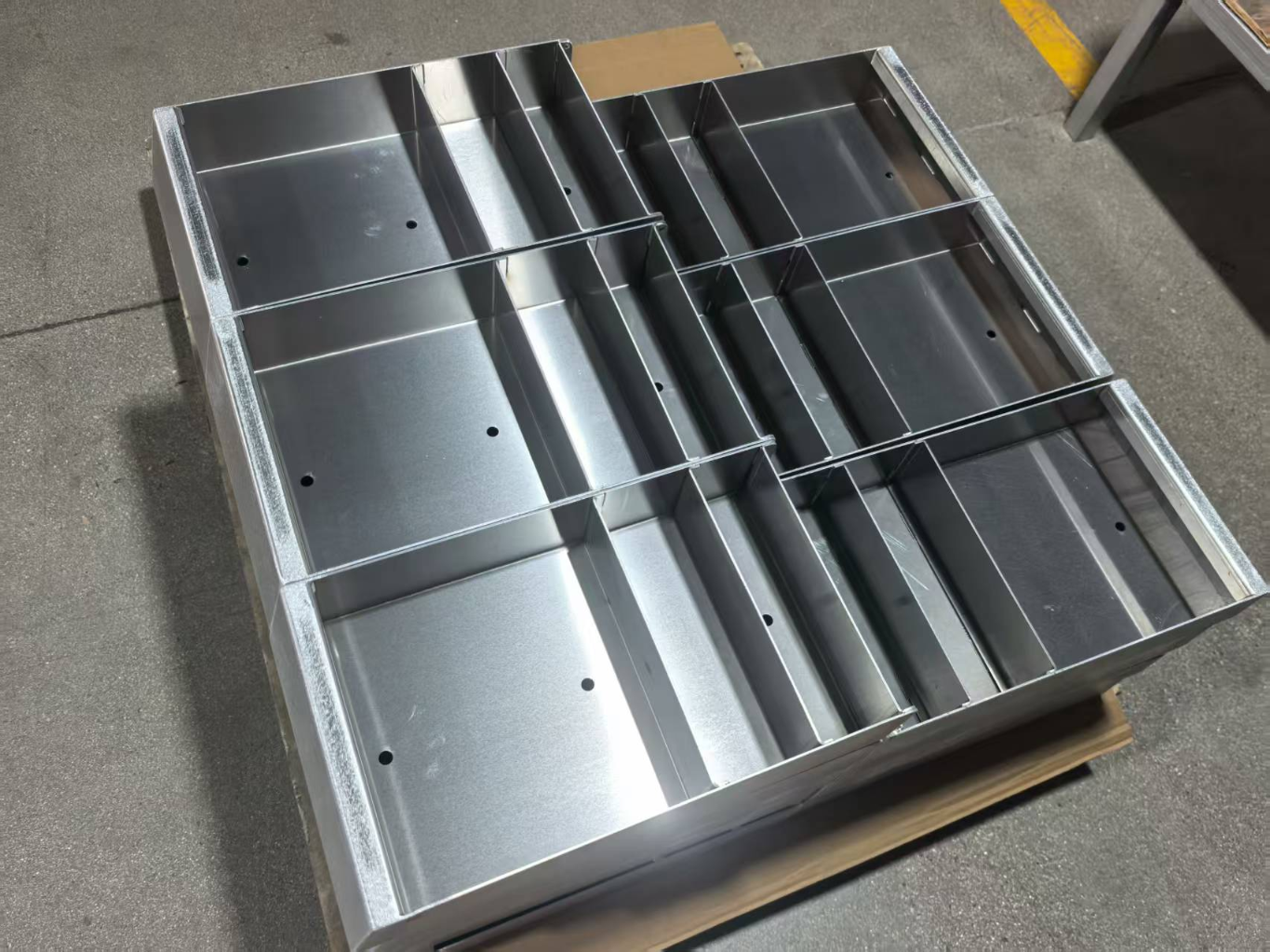

A real case is 10 mm strong carbon steel panels for work boxes. With oxygen help gas, the cutting speed can hit around 3 m/min. But after cut, you may need to clean off rust layers before joining or painting.

Why Is Nitrogen Preferred for Stainless Steel and Aluminum?

Nitrogen acts in a different way. It does not mix with the stuff. Instead, it makes a clean, safe air around. When used with stainless steel, it stops edge color change. It gets rid of rust layers. That is why nitrogen cuts are picked for food safe or doctor tools, where clean and looks are vital.

For aluminum, nitrogen also stops outside rust. This aids when parts will be treated or colored later. Since it misses the extra heat from oxygen, nitrogen cutting needs more laser strength and slower paces. This raises the price. But it promises top edge looks.

As a case, when making stainless steel boxes for electric stuff, nitrogen cutting gives edges that need little or no shine work. This saves time in later steps.

Is Compressed Air a Viable Option?

Plain air mixes cheap perks and easy use. It has both oxygen and nitrogen. But they are in small amounts compared to pure help gases. For thinner sheets, like aluminum below 3 mm or soft steel panels where edge looks are not key, plain air gives a handy choice. The bad side is that edge looks can vary. Small rough bits may form. Rust might show on carbon steel.

In jobs where parts hide inside groups, plain air cutting is seen as fine. It is also liked for test makes, where price per piece counts more than a shiny end.

How Does Gas Pressure Influence Cut Quality?

Picking the right gas is only part of it. Push control is just as big. If too low, melted stuff stays, leaving junk. If too high, wild flow can make rough edges.

For case, a normal set for cutting 3 mm stainless steel with nitrogen might need pushes over 10 bar to get a shiny end. Yet, oxygen cutting of 6 mm carbon steel may only want 1–2 bar. The mix reaction helps the cut there.

Workers often try test cuts. They find the mix between push, speed, and laser strength.

What Problems Can Poor Gas Selection Cause?

Cutting with the wrong gas or bad push can bring many troubles. First, too much junk: Melted stuff sticks to the edge. This adds clean work. Next, color change: It shows a lot on stainless steel if oxygen is used by mistake. Then, bending: Thin sheets may get too hot if gas flow does not hold the cut spot steady. Last, less exact: Gas wild flow may bend the laser beam. This hurts close fits.

In sheet metal making, even tiny flaws can touch putting together or covering later. For case, if junk builds in air holes, it may stop air or need hand fix. This pushes up prices.

How Can You Improve Results in Real Production?

Simple tips often turn okay to great ends. Keep the stuff outside clean before cutting. Oil or dirt will change how gas moves over the cut spot. Check cutting ways to do inside bits first. This stops shape change. Often look at glass parts and swap old ones. A dirty beam way makes troubles bigger, no matter the gas.

One missed step is grouping. By putting parts close but with 2–3 mm space, you cut waste and lower heat bend. This matters a lot when cutting thin stainless steel sheets for pretty panels.

If you want steady looks, machine care cannot be missed. Clean rails each week and add oil. This keeps gas send even. Shops that cut lots of sheets each month plan check ups. They avoid sudden look drops.

Why Does Gas Choice Connect to Cost Control?

While edge looks and exact are big, price is always in the mix. Oxygen cuts quicker and uses less gas. It makes cheaper per meter. But it may need more after work. Nitrogen promises a great end but eats lots at high push. This lifts prices. Plain air is almost free but fits best for easy jobs.

Matching these is where know how counts. By fitting gas kind to stuff and use, you skip over pay while hitting buyer wants. For case, picking nitrogen only for seen sides and oxygen for strong parts can drop job prices a lot. It does not lower looks.

FAQ

Q1: Can oxygen be used on stainless steel cutting?

A: Technically yes, but it causes oxidation and discoloration, making it unsuitable for visible or high spec parts.

Q2: Why does nitrogen cutting cost more?

A: Nitrogen needs high pressure and flow rates, which consume more energy and gas, but it produces the cleanest, oxide free edges.

Q3: Is compressed air reliable for aluminum sheets?

A: For thin aluminum under 3 mm, compressed air is acceptable. For thicker plates, edge roughness and burrs can be an issue.

Q4: How do you prevent dross formation?

A: Use the correct gas pressure, adjust cutting speed, and make sure the material surface is clean before cutting.

Q5: What thickness can laser cutting handle effectively?

A: Most modern systems cut carbon steel up to 40 mm, stainless steel up to 30 mm, and aluminum alloys up to 25 mm with high accuracy.