Custom Sheet Metal Fabrication Spotlight: Weld Joints

Time : Oct 16, 2025 View : 321

Why Weld Joints Matter in Sheet Metal Fabrication

In custom sheet metal work, most people first think about cutting or bending. But in reality, the way sheets are joined plays an even bigger role. Weld joints often decide the strength, look, and lifetime of the final product. A weak weld may crack, leak, or bend out of shape. A strong, well made joint can last for many years with little trouble. In fields like automotive, aerospace, and electrical enclosures, this difference is clear. Weld joints are not small details. They are the backbone of the structure.

Main Types of Weld Joints in Sheet Metal

Butt Joint

This is the simplest joint form. Two sheets with the same thickness are put edge to edge and then welded. It gives a clean and flat result. Butt joints are common in car body panels and repair work. The challenge is that edges must be prepared well. If the heat is not right, you risk incomplete fusion.

Lap Joint

Here, one sheet overlaps another. The weld then locks them together. It has good shear strength and is more forgiving if alignment is not perfect. That’s why it is often used in thin sheet parts. But the overlap means more material, and if not sealed, water or dirt can get into the lap. That can lead to corrosion over time.

T Joint

This looks like a “T” shape, where one sheet stands against the middle of another. These joints are widely used in frames and supports. They need deep penetration and steady heat control. Without that, distortion can happen. If you see a frame twist after welding, it usually means the weld sequence or the clamping setup was not done correctly.

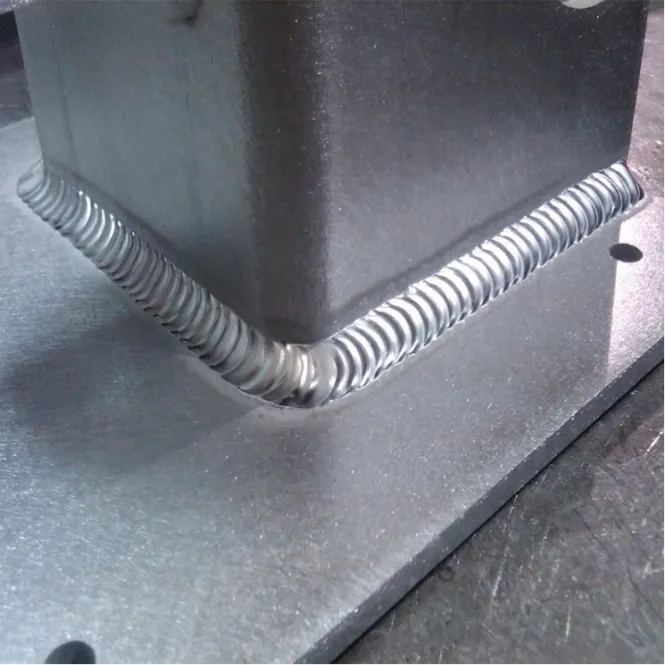

Corner and Edge Joints

Corners show up everywhere, cabinets, boxes, and cases. Edge joints are chosen when two sheet edges meet but do not need to bear heavy loads. They are also used when sealing or neat appearance is required. Smooth corners save time because less grinding and polishing is needed later.

Key Factors That Influence Weld Joint Quality

Material Properties

Different metals behave differently under heat. Aluminum spreads heat so quickly that it can burn through. Stainless steel can warp if heat is not managed. Carbon steel is easier to weld but still needs proper handling. Knowing the material is always the first step.

Welding Methods

TIG, MIG, spot welding, and laser welding all have their uses. TIG is slow but gives clean and precise welds. MIG is faster and suits mass production. Spot welding is perfect for thin overlapped sheets like those in car panels. Laser welding offers narrow, accurate seams for high end parts.

Joint Preparation

Good preparation is half the job. Cleaning away oil, rust, and oxides prevents pores in the weld. Beveling thicker sheets at 30–60° helps the weld reach full depth. Skipping prep may save minutes, but fixing a failed weld later costs far more time.

Heat and Distortion Control

Thin sheets cannot handle too much heat. To control this, welders use skip welding, backstep welding, or copper chill bars. These methods spread or absorb heat so the sheet stays flat. Sometimes, the best weld is simply the one with less heat input.

Weld Joints in Real World Applications

Automotive: Lap joints and spot welds dominate in car body assembly. Butt joints are seen in repair jobs.

Electrical Cabinets: Corners and seam welds give both strength and a neat outside look.

Aerospace: Lightweight aluminum structures rely on butt and T joints, often made by TIG welding.

Industrial Frames: T joints and lap joints deliver the stiffness needed for heavy machine housings.

If you open up a metal cabinet or an appliance, you’ll see more than one type of joint. Each joint is picked for a reason: strength, load, or finish.

How Weld Joints Are Inspected and Tested

Non Destructive Testing

Dye penetrant testing (ASTM E1417) and ultrasonic inspection are widely used. They catch cracks and incomplete fusion without cutting the part open.

Mechanical Testing

Tensile and shear tests check if the weld can keep at least 85–95% of the original base metal strength. Macro etch inspection is used for checking full penetration.

Post Weld Treatments

Grinding and polishing improve appearance. For aluminum, anodizing or conversion coatings add protection. In some projects, vibration stress relief helps reduce built up stress without high heat.

Future Trends in Sheet Metal Welding

Laser Welding: Creates narrow, deep welds with little distortion. Ideal for thin materials.

Robotic Welding: Ensures steady quality and fast repeatability in large runs.

Smart Sensors: New systems watch the weld pool in real time and cut defects before they happen.

Green Practices: More energy saving methods and safer fume extraction are becoming standard.

While technology keeps improving, the basics stay the same: prepare well, pick the right method, and control the heat.

Conclusion

In custom sheet metal fabrication, weld joints decide far more than just how parts stick together. They shape the durability, the reliability, and even the look of the product. Choosing the correct joint, preparing carefully, and controlling the weld are the keys to success.

Deshibo applies these principles every day, combining cutting, bending, and welding skills to deliver dependable custom sheet metal parts for many industries.

FAQ: Weld Joints in Custom Sheet Metal Fabrication

1. What is the strongest weld joint for sheet metal?

T joints and fully penetrated butt joints are usually strongest, but it depends on the design and load.

2. How does TIG welding compare to MIG for thin sheet metal?

TIG gives finer welds with more control. MIG is faster and works better for big production jobs.

3. Can aluminum sheets be welded without distortion?

Yes, but only with strict heat control. Pulsed TIG and chill bars help reduce warping.

4. What standards are followed for weld quality?

Shops often follow AWS D1.2 for aluminum and AWS D1.1 for steel fabrication.

5. How do weld joints affect cost?

Complicated welds like multi pass corners take more time and cost more. Simple joints like lap or spot welds are faster and cheaper for bulk work.