Common Problems in Metal Bending and How Laser Tech Solves Them

Time : Sep 26, 2025 View : 435

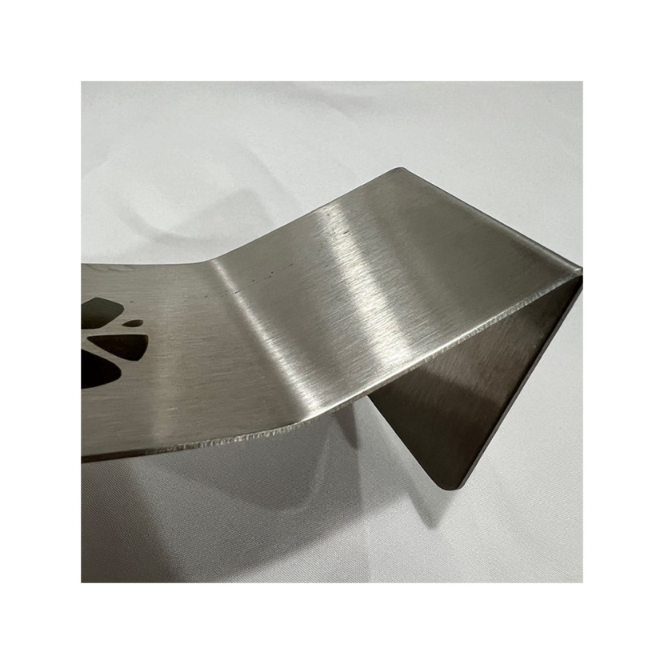

Metal bending has been at the heart of modern sheet metal fabrication for decades. From creating small brackets to large automotive panels, bending defines how flat sheets turn into three dimensional parts. But bending metal is not always straightforward. If you’ve worked in fabrication, you’ve likely seen cracking, springback, or even tool collisions. These challenges cost time, waste material, and sometimes make a design unworkable. In this article, you’ll see the common bending problems and how modern metal laser bending technology helps overcome them.

Why Metal Bending Faces Problems

Thin Sheet Sensitivity

Thin sheets deform easily. While this is great for forming, it also means poor resistance to bending stress. Materials like SPCC cold rolled steel or 0.8 mm aluminum often crack or wrinkle if the bend radius is too tight. Designers are advised to avoid very small inner radii and to add round corners at stress zones.

Tooling and Minimum Heights

Each thickness of sheet corresponds to a minimum bending height. For example, for 1.5 mm steel, the minimum safe flange height is about 6.3 mm, with 5.3 mm as the limit. If the design only leaves 4.2 mm, bending becomes almost impossible without costly extra machining.

Interference With Tools

When the distance between a bend and a nearby edge is too short, the punch may collide with the material. This happens in complex parts with multiple bends at tight spacing. Traditional shops often solve it by milling off extra material, which increases cost and lowers efficiency.

Springback and Accuracy Issues

Springback is the rebound that happens after bending. It depends on material hardness, thickness, and radius. The larger the inside radius, the greater the springback. Without compensation, parts deviate from their intended angle, causing poor assembly fit.

Common Problems in Metal Bending

Cracks at the Bend Line

When the bend radius is too small, materials like stainless steel or hardened copper may crack. For SPCC and general steels, the minimum bend radius is usually 0.4–0.6 times the thickness. For high strength steels like 65Mn, it can be 1.5–2 times the thickness.

Deformation Around Holes

If a hole sits too close to the bend area, it distorts during forming. Best practice is to keep the hole edge at least two times the material thickness away from the bend root. Otherwise, oval holes or misaligned fasteners result.

High Cost From Poor Design Choices

Designs with tiny protruding flanges or narrow slots waste material and require complex tooling. For instance, small support tabs for PCBs can be redesigned as welded or riveted posts to save material and simplify forming.

Collision and Interference

Many bending problems stem from ignoring the actual shape of the press brake punch and die. If designers don’t simulate the process, the tool collides with the material, leaving dents or stopping production altogether.

Riveting and Fastener Distortion

In cases where clinching nuts are placed too close to edges, deformation occurs during riveting. The paint layer can crack, forcing workers to grind and repaint, slowing down production and raising cost.

How Laser Technology Provides Solutions

Precise Cutting Before Bending

Laser cutting allows accurate pre cut slots, relief holes, or chamfers before bending. This prevents stress concentration and reduces cracking risk. For example, adding a relief notch at a bend line allows controlled deformation without tearing.

High Accuracy and Repeatability

Laser systems cut within ±0.1 mm tolerance. When combined with CNC bending, you get parts with consistent angles and dimensions, reducing rework.

Freedom for Complex Designs

Traditional punching struggles with very small slots or intricate patterns. Laser cutting produces any geometry, letting you design bend reliefs, tabs, or curved profiles without tooling changes.

Reduced Secondary Operations

Without laser cutting, fabricators often mill or grind to avoid collisions. Laser processing eliminates this by creating precise clearances beforehand. That means lower cost and faster turnaround.

Integration With Smart Manufacturing

Today’s metal laser cutting and bending solutions are integrated into digital workflows. CAD drawings go directly to CNC machines, minimizing errors and ensuring what you design is exactly what you receive.

Real World Application Example

Consider a 1.5 mm steel bracket requiring a 90° bend with a short flange. Using conventional tooling, the 4.2 mm flange height was below the limit, causing tool interference. Shops had to increase flange size, then machine it back, wasting time and material. By combining laser cutting with CNC bending, relief slots were added, allowing a clean bend without secondary milling. This cut production cost and improved throughput.

About Yantai Deshibo

When dealing with such challenges, you need a partner that can handle the full cycle of sheet metal production. Yantai Deshibo specializes in sheet metal manufacturing and CNC machining, offering complete end-to-end solutions. From services like cutting, bending, and welding to final finishing, the company delivers parts with precision and consistency. Deshibo not only supports bending but also provides related solutions in enclosures, brackets, and assemblies. You can explore more details on their about us page or get direct project advice via their contact page.

Key Takeaways for Designers and Fabricators

Always check minimum bend radii and heights based on material thickness.

Keep holes and slots away from bend lines to prevent distortion.

Simulate tooling paths early to avoid collisions.

Use laser cutting to add reliefs and reduce cracking.

Consider total cost of fabrication, not just the initial design simplicity.

FAQ

Q1: What is the minimum bend radius for common steels?

A: For mild steels like SPCC, the minimum bend radius is about 0.4–0.5 times the material thickness. Harder alloys may need up to 2 times the thickness.

Q2: How do you avoid springback in bending?

A: You can reduce springback by choosing smaller bend radii, increasing forming pressure, or adding strengthening ribs in the bend area.

Q3: Why do holes deform near a bend line?

A: Holes too close to the bend root distort during forming. Keep the hole edge at least 2t away from the bend root to avoid this problem.

Q4: How does laser cutting improve bending quality?

A: Laser cutting creates precise relief notches, slots, and accurate edges. This lowers stress concentration, prevents cracking, and makes bending easier.

Q5: What industries benefit most from laser cutting and bending?

A: Automotive, aerospace, electronics enclosures, and construction benefit heavily. They need accuracy, repeatability, and the ability to handle complex geometries quickly.