Are You Using the Right Bend Radius for Your Precision Sheet Metal Formed Part?

Time : Oct 02, 2025 View : 424

Introduction to Bend Radius in Sheet Metal Forming

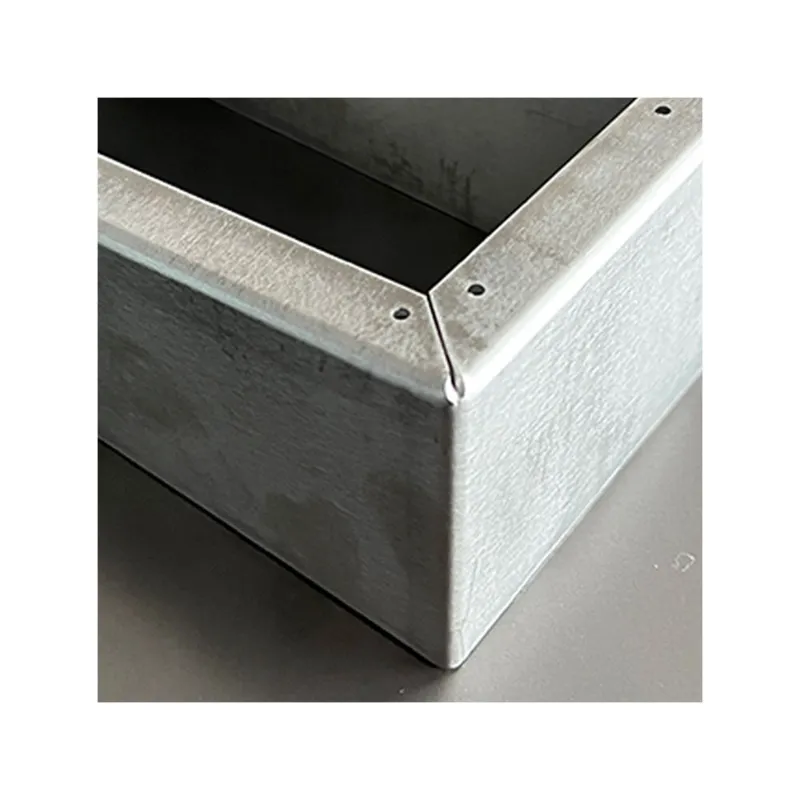

Look around at everyday items like kitchen gadgets or car frames, sheet metal parts are all over. They’re lightweight, sturdy, and simple to mold. A vital part of molding them is the bend radius, which is the curve created when metal bends. Picking the perfect bend radius isn’t just a small detail. It strongly shapes the part’s strength, look, and price.

Many designers and buyers miss this point. They think about design or material types but forget how bend radius works with thickness, tools, or grain direction. What happens? Cracks, wasted materials, or pricey fixes. That’s why companies like Deshibo, who offer full sheet metal solutions, focus heavily on bend radius from the design’s start.

Why Bend Radius Matters in Precision Sheet Metal Parts

Impact on Structural Integrity

A bend radius that’s too tiny can quickly cause cracks, especially in tough materials like stainless steel. Sheet metal design rules say the smallest inner radius for many steels should be at least 0.4–0.6 times the material thickness. For stronger alloys, it jumps to 2.0t. If you skip this, parts might break during use. This leads to costly repairs or replacements.

Influence on Dimensional Accuracy

Bending alters the metal’s flat length. If designers misjudge the bend allowance or ignore springback, the parts won’t fit together. Even a tiny 0.5 mm mistake across several bends can mess up holes, slots, or mounting spots.

Effect on Aesthetic and Surface Finish

Tight bends often cause scratches, wrinkles, or odd shapes. For parts like visible covers or decorative panels, this ruins their charm. A smoother bend radius, however, keeps both function and beauty intact.

Key Factors That Determine the Right Bend Radius

Material Type and Thickness

Each material bends differently. Aluminum is easier to work with, but stainless steel cracks more easily. Data from standards shows:

Mild steel (SPCC, Q235): minimum radius 0.5t

Brass and copper: around 0.8t

Hardened stainless (SUS301, SUS302): 2.0t or more

Thicker sheets need bigger radii to bend safely.

Grain Direction in Sheet Metal

Bending along the metal’s grain makes cracks more likely. Bending across the grain boosts flexibility and lowers cracking risks.

Tooling and Press Brake Capabilities

The tools you pick directly affect the bend radius. For instance, a V die with a wider gap creates a larger radius. Modern CNC press brakes give steady results. Still, workers must choose the correct die width based on the material’s thickness.

Common Mistakes When Choosing Bend Radius

Ignoring Material Specifications

A big error is using the same bend radius for every material. This might be okay for test models, but it causes problems in full production.

Overlooking Manufacturing Tolerances

Designs sometimes miss giving enough space for bends near holes or edges. If holes are too close to the bend line, they warp. The safe gap is usually at least 2t from the bend radius.

Prioritizing Cost Over Quality

Some folks try to save money by using fewer tool switches and forcing tight bends on all materials. This seems smart at first, but it creates more scrap. In the end, it costs more than doing it right from the beginning.

How to Choose the Correct Bend Radius

Follow Industry Standards and Guidelines

Standards like GB, ISO, and ASTM offer helpful charts for minimum bend radii for various materials. These charts are handy during design. They help dodge expensive errors.

Work with Engineers Early in the Design Stage

Teaming up with manufacturing engineers early makes a big difference. It cuts down on fixes later. Many suppliers offer full services from design to production.

Prototype and Test Before Mass Production

Before finalizing the design, smart companies make a small batch using metal laser cutting and bending. Testing checks if the bend radius works for strength and looks.

Case Study: Real Results of Correct Bend Radius

A clear example comes from consumer electronics housings. A Chinese factory making stainless steel back covers for kitchen appliances had a 15% scrap rate due to cracks from sharp bends. By switching the bend radius from 0.5t to 1.5t, cracks vanished. The surface looked better, and the scrap rate fell below 2%. This case proves how one small design tweak can boost quality and save money.

Conclusion and Best Practices

Bend radius isn’t just a number on a sketch. It’s a key factor that affects cost, strength, and usability of sheet metal products. The best steps are:

Stick to bend radius values specific to each material

Think about thickness, grain, and tools

Test with prototypes before making lots of parts

For buyers and engineers, partnering with skilled companies like Deshibo is crucial. Their focus on precision, speed, and customer friendly solutions helps turn ideas into real products. Want to talk about your project? You can request a quote here.

FAQ: Bend Radius in Sheet Metal Forming

Q1: What is the minimum bend radius for aluminum sheets?

For grades like 1100 H24, the smallest inner bend radius is about 0.4t. So, for a 2 mm thick sheet, the safe radius is around 0.8 mm.

Q2: How does sheet thickness affect bend radius?

Thicker sheets need bigger bend radii. A 1 mm sheet might bend fine at a 0.5 mm radius, but a 5 mm sheet could need a 5 mm radius or more.

Q3: Can I use the same bend radius for steel and stainless steel?

Not always. Mild steel bends tighter than stainless steel. Stainless needs a larger radius to avoid cracks.

Q4: What happens if the bend radius is too small?

You might see cracks, wrinkles, or springback problems. The part may not fit right or could break under pressure.

Q5: How do I check if my bend radius design is manufacturable?

Talk to your sheet metal supplier. Many offer design for manufacturing (DFM) checks and prototype samples before full production.