7 Considerations for Spot Welding Precision Sheet Metal Parts

Time : Jul 24, 2025 View : 673

Material Selection and Its Impact on Spot Welding

How Different Metals Respond to Sheet Metal Spot Welder Techniques

Different metals act in their own way when using a sheet metal spot welder. This happens because each metal has unique features like how it conducts electricity, handles heat, or forms surface layers. For example, low carbon steel works great for spot welding. It has just the right amount of electrical resistance and bends easily. But aluminum is trickier. It conducts heat fast and forms an oxide layer, which makes spot welding harder.

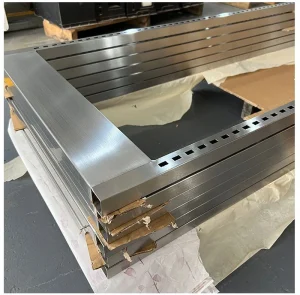

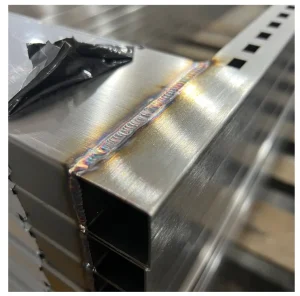

When it comes to spot welding stainless steel sheet, you need careful control. Stainless steel resists electricity more than mild steel. This causes quick heat buildup at the weld spot. It’s easier to make a weld nugget, but too much heat can burn through or twist the metal if you’re not careful. Yan Tai Deshibo Metal Products Co., Ltd. uses special sheet metal spot welder machines. These have adjustable settings for electrode force and current. This ensures steady welds without harming the surface.

Challenges of Spot Welding Stainless Steel Sheet

Spot welding stainless steel sheet brings a few problems. Its high electrical resistance creates a lot of heat. The oxide layer on the surface lowers conductivity. Also, stainless steel doesn’t spread heat well, so it can warp easily. Plus, many projects need the metal to look nice after welding. This means you must control the weld’s appearance carefully.

Yan Tai Deshibo tackles these issues with three main methods:

Cleaning the surface before welding using tools or chemicals.

Using coated electrodes to avoid sticking and keep welds clean.

Finishing welds with grinding or brushing for parts that need to look good.

The Role of Material Thickness in Weld Quality

Spot welding works best on materials between 0.020” and 0.090” thick. If the metal is too thin, it might burn through. If it’s too thick, the weld may not hold well without using too much current, which can damage the part. For thicker metals, plug welding is often better. Yan Tai Deshibo picks the right electrode size, current, and weld time based on the metal’s thickness. This keeps the welds strong and the part’s shape and look intact.

Design Factors That Influence Spot Welding Outcomes

Importance of Weld Accessibility in Sheet Metal Welding

Your design must let welding electrodes reach the spot easily, especially for tricky shapes. If electrodes can’t get to the right place or press evenly, you might get weak or bad welds. Yan Tai Deshibo’s CAD designers check electrode paths during the design stage. They make sure everything is reachable before starting sheet metal welding.

Optimizing Joint Design for Effective Spot Welds

Good joint design makes spot welding better. Overlapping joints with enough flange width help electricity flow and spread heat evenly. With a spot welded part, you can design it so the metal overlaps itself. This avoids the need for grinding after welding. It gives a smooth, Class A finish right away, which is great for products people see, like appliances or car parts.

Avoiding Warping and Distortion During Welding

Heat can twist thin sheets, like stainless steel, during welding and sheet metal work. This is a big issue for large flat panels or precise parts. To prevent this, Yan Tai Deshibo uses alternating weld patterns. They also control cooling times during production to keep the metal from warping.

Equipment Calibration and Maintenance for Consistent Results

Setting the Correct Parameters on a Sheet Metal Spot Welder

Good spot welding needs the right settings. These include current, electrode force, weld time, and hold time. Each must match the metal type and thickness. Yan Tai Deshibo’s engineers set their sheet metal spot welder for each job. They use systems that watch and adjust settings in real time during production.

Regular Maintenance to Ensure Stable Weld Performance

Without regular care, welding machines lose performance. Dirty contacts or worn parts can cause weak voltage or uneven pressure. Yan Tai Deshibo checks their equipment every 500 hours. They inspect transformers, cables, cooling systems, and actuators to keep everything working well.

The Impact of Electrode Condition on Spot Welding Quality

Electrode condition is super important. If electrodes are worn or shaped wrong, they press unevenly. This leads to uneven heat and weak welds or burn-throughs. Deshibo’s team reshapes electrodes with special tools. They replace them when the tip size goes beyond AWS standards.

Precision in Electrode Force and Alignment

Controlling Electrode Pressure for Accurate Spot Welding

Too much pressure can push molten metal out of the joint. Too little pressure won’t fuse the metal properly. Yan Tai Deshibo uses controlled pneumatic systems. These keep electrode force within ±5% for every batch, ensuring the same results even if conditions change.

Aligning Electrodes to Prevent Inconsistent Welds

If electrodes aren’t lined up right, weld nuggets form off-center. This makes welds weak. Yan Tai Deshibo uses laser-guided systems to set up electrodes accurately before starting big production runs.

Heat Control and Weld Timing Considerations

Managing Heat Input for Thin Precision Sheets

Thin sheets, like 0.5mm stainless steel, can overheat during spot welding stainless steel sheet. To avoid this, use:

Lower current settings

Shorter weld times

Longer hold times after welding to let the metal cool

Deshibo programs these settings into their automated sheet metal spot welder machines. They use client CAD files to match the metal’s thickness.

Adjusting Weld Time for Different Materials and Thicknesses

Welds outside the 0.020”–0.090” range need different timing. For example:

Aluminum needs longer preheat times.

Stainless steel needs short, strong pulses.

Deshibo adjusts these using programmable logic controllers (PLCs) in their robotic welding setups for each job.

Surface Preparation Before Spot Welding Stainless Steel Sheet

Cleaning Techniques to Improve Electrical Conductivity

Dirt, oil, or rust on metal surfaces blocks electricity during spot welding. Clean surfaces are a must. Yan Tai Deshibo uses ultrasonic cleaning and alcohol wipes before loading parts into their welders. This ensures good electrical flow at every weld point.

Removing Oxides and Coatings That Affect Weld Integrity

Stainless steel forms an oxide layer that messes with spot welding stainless steel sheet. Removing it helps the weld fuse better. Deshibo uses light brushing and sometimes acid pickling before welding. This is especially key for aerospace parts where strong welds are critical.

Frequently Asked Questions (FAQ)

What thickness range is ideal for spot welding sheet metal?

Spot welding works best for materials between 0.020”–0.090” thick. Thinner metals might burn through. Thicker ones may need methods like plug welding.

How do you prevent warping when spot welding stainless steel?

Use staggered weld patterns. Clamp parts tightly during welding. Keep heat low with short cycles. Allow cooling between welds. Yan Tai Deshibo follows these steps carefully.

Can I get cosmetic-quality finishes directly after spot welding?

Yes! With overlapping designs made for Class A finishes, no grinding is needed after welding and sheet metal. This saves time and money while looking great.

Why does electrode condition matter so much?

Worn electrodes cause uneven pressure. This leads to weak joints or overheating. Regular reshaping ensures steady contact, as Deshibo does per global standards.

What makes Yan Tai Deshibo suitable for custom sheet metal fabrication?

Yan Tai Deshibo Metal Products Co., Ltd. offers full services. They provide CAD design, CNC machining, bending, forming, and welding and sheet metal work. They handle metals like stainless steel and aluminum. They also offer finishes like anodizing or powder coating. All this happens in one place for top-quality results.

For precise sheet metal welding backed by expert spot welding stainless steel sheet techniques, contact Yan Tai Deshibo Metal Products Co., Ltd. today! Their team turns your ideas into finished products with great quality from start to end.