4 Things You Didn’t Know About Aluminum Fabrication

Time : Aug 14, 2025 View : 566

Unique Properties That Make Aluminum Ideal for Fabrication

Why Aluminum is Preferred in Sheet Metal Projects

Aluminum’s a real winner for aluminum sheet metal fabrication because it’s got this wicked combo of features. You can slice, fold, or twist it with plain old tools, no sweat. It’s free of iron, so it doesn’t get all rusty like steel. That makes it solid for projects indoors or out in the rain. Plus, it’s ace at moving heat and electricity, so it’s spot-on for stuff like gadget cases or parts that gotta stay chill.

The Lightweight Advantage in Aluminum Sheet Metal Fabrication

One thing that makes aluminum stand out is how feather-light it is. It’s about one-third as heavy as steel, so you can whip up parts that are tough as nails but don’t weigh you down. This is a game-changer for things like planes, cars, or phones, where dropping weight means they zoom better and save gas without being wimpy.

Corrosion Resistance and Its Impact on Product Longevity

Aluminum throws up a thin wall on its surface that keeps rust at bay. If that wall gets dinged, it patches itself up in a snap, shielding the metal from rain, air, or nasty chemicals. In harsh spots like the ocean or gritty factories, this trick lets aluminum sheet metal fabrication parts stick around for ages.

The Role of Alloys: Comparing 5052, 6061, and 7075 Aluminum

Key Characteristics of 5052 Aluminum Alloy

The 5052 aluminum alloy is a beast at dodging rust and holding strong under pressure. It’s a breeze to shape, which is why it’s big in boats that deal with salty waves. You can also bend it into wavy shapes for things like building panels or gas tanks.

Strength and Versatility of 6061 Aluminum Alloy

The 6061 alloy is like the Swiss Army knife of aluminum. It’s got muscle, welds like a charm, fights rust, and machines without a hitch. People use it for stuff like frames, brackets, or pipes. In aluminum sheet metal fabrication, 6061 nails CNC tasks like drilling or turning and stays rock steady no matter what.

High-Performance Applications of 7075 Aluminum Alloy

When you need something stupidly strong, 7075 aluminum alloy is the one to call. It’s tough like some steels but doesn’t weld as easy or keep rust off as well as other alloys. You’ll see it in plane parts or sports gear that takes a serious beating.

Choosing the Right Alloy for Your Fabrication Needs

Picking the perfect alloy depends on what your project’s yelling for. Want rust protection? 5052’s got your back. Need a jack-of-all-trades? 6061’s your guy. Craving max strength? 7075’s the ticket. A quick chat with the pros at Yan Tai Deshibo Metal Products Co., Ltd. helps you snag the alloy that fits your vibe and budget.

|

5052 Aluminum Alloy |

6061 Aluminum Alloy |

7075 Aluminum Alloy |

WINNER |

|

|

Strength |

GOOD |

GOOD |

EXCELLENT |

7075 |

|

Formability |

EXCELLENT |

FAIR |

FAIR |

5052 |

|

Weldability |

EXCELLENT |

EXCELLENT |

GOOD |

5052, 6061 (tie) |

|

Rust Resistance |

GOOD |

GOOD |

GOOD |

TIE |

Advanced Techniques in Aluminum Sheet Metal Fabrication

Innovations in Laser Cut Aluminum Sheet Technology

Laser cutting’s flipped the script on shaping aluminum sheets. It keeps the heat low and cuts crazy precise, so you can craft wild designs without trashing the metal. Laser cut aluminum sheets are clutch for clean edges or super tricky patterns. Yan Tai Deshibo Metal Products Co., Ltd. rolls with high-tech fiber lasers to zip through aluminum with dead-on accuracy.

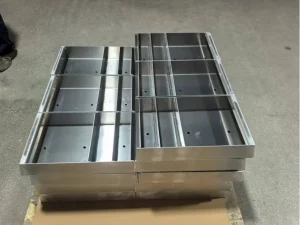

Precision and Efficiency in Aluminum Sheet Metal Stamping

Aluminum sheet metal stamping is a total win for cranking out parts like nobody’s business. It uses custom molds to smash aluminum into shapes like boxes or plates. You can punch holes or toss in bends in one go, which keeps things quick and the work humming along.

CNC Machining and Its Role in Custom Aluminum Parts

CNC machining’s where it’s at for nailing super exact aluminum parts. At Yan Tai Deshibo Metal Products Co., Ltd., we do the whole deal—milling, drilling, turning, grinding—all dialed in for aluminum alloys. Hand us your doodles or CAD files, and we’ll pump out parts you can bank on every time.

End-to-End Solutions Streamline the Manufacturing Process

Integrating Design, Cutting, Bending, and Assembly Services

Hooking up with a one-stop shop makes things a breeze. They tackle design, cutting, bending, and assembly all in one place. That means less waiting around and top-notch quality. Yan Tai Deshibo Metal Products Co., Ltd. handles laser cut aluminum sheet work, bending with press brakes, welding (MIG, TIG, or spot), coatings like anodizing or powder, and slapping it all together, all under one roof.

Benefits of Outsourcing to a Full-Service Fabrication Partner

Dumping the work on a pro team lets you focus on your thing, like dreaming up new products or selling them. When one crew handles the whole gig, you save cash on stuff like hiring or gear. Yan Tai Deshibo Metal Products Co., Ltd.’s tight setup means you get killer quality, whether it’s one part or a boatload.

How In-House CAD Support Enhances Customization Capabilities

Our CAD squad takes your brainstorms and turns them into real-dealdesigns, whether you’ve got a quick sketch or a full-on blueprint. We tweak stuff to use less material, which is huge with pricey aluminum alloys. Yan Tai Deshibo Metal Products Co., Ltd.’s custom game makes sure your project pops just how you want.

Frequently Asked Questions (FAQ)

What are the main benefits of using aluminum sheet metal fabrication?

Aluminum’s light but burly, doesn’t rust easy, shapes like a dream, and moves heat like nobody’s business. That makes it perfect for all sorts of stuff, from covers to building bits.

Which industries benefit most from CNC machined aluminum parts?

Places like planes, cars, gadgets, and medical gear eat up CNC machining. It churns out spot-on parts from light, tough aluminum alloys.

How does anodizing differ from powder coating?

Anodizing throws on a hard layer to stop rust and keep parts strong. Powder coating adds a colorful coat for style and protection from dings.

Can I provide my own design files for manufacturing?

Heck yeah! Yan Tai Deshibo Metal Products Co., Ltd.’s crew can roll with your CAD files or help whip some up to make your parts just right.

Why should I choose a full-service fabricator instead of managing vendors separately?

A one-stop shop takes care of design to assembly in one shot. It saves time and keeps quality tight from start to finish.

To check out how Yan Tai Deshibo Metal Products Co., Ltd., champs in aluminum sheet metal fabrication and CNC machining, can juice up your next project, hit us up today! We’ve got the full package, from design help to finishing for aluminum and stainless steel.